When you need a single solution for sealing, insulating, or repairing a wide variety of surfaces, what product comes to mind? If you’re like many professionals and DIYers, aluminum tape is likely at the top of your list. But what exactly makes this tape so indispensable across so many industries and home projects?

Aluminum tape—sometimes called aluminum foil tape—features a unique structure: a thin, flexible layer of aluminum foil bonded to a pressure-sensitive adhesive. This combination creates a tape that is not only easy to apply but also exceptionally durable. Imagine working on a project where you need a material that can resist heat, moisture, and harsh chemicals; this is where aluminum tape truly shines.

Sounds complex? Not at all! The beauty of aluminum tape lies in its simplicity and effectiveness. Whether you’re a contractor sealing HVAC ductwork, a homeowner patching a leaky roof, or a hobbyist working on electronics, you’ll notice its versatility in action. Its uses span:

For a deeper dive into why aluminum tape is the go-to choice for so many professionals, check out this detailed blog post by Shengxin Aluminum that explores its essential properties and real-world applications.

In the chapters ahead, we’ll explore everything from the science behind aluminum tape’s performance to practical tips for choosing the right product for your project. Expect insights on HVAC, insulation, electronics, lighting, and more—so you can unlock the full potential of this remarkable adhesive solution.

Ever wondered what makes aluminum tape so effective for everything from HVAC repairs to electronics? The secret lies in its carefully engineered structure and the science behind its unique set of properties. Let’s break down what goes into this versatile adhesive and why it performs so reliably in tough conditions.

What sets aluminum tape apart from other tapes isn’t just its construction, but the specific properties it brings to your project. Here’s what you can expect when you use quality aluminum foil tape:

Imagine sealing an HVAC duct exposed to both summer heat and winter cold, or wrapping cables in an electronics project that demands both thermal and EMI protection. The combination of a metal foil barrier, advanced adhesive, and protective liner means aluminum tape can meet these diverse challenges head-on. Its unique blend of aluminum foil tape properties—from thermal conductivity to moisture resistance—explains why it’s trusted in so many industries.

Now that you know what’s inside every roll, let’s see how these features translate into real-world performance—starting with its critical role in HVAC systems.

When you think about what keeps your home comfortable year-round, you might picture your furnace or air conditioner. But have you ever considered the silent workhorse behind the scenes—your ductwork? Even the best HVAC systems can lose efficiency if the ducts aren’t properly sealed. That’s where hvac aluminum tape comes in, providing a reliable solution for creating airtight, energy-efficient ductwork.

Imagine a scenario where conditioned air escapes through tiny gaps in your duct system. Not only does this mean wasted energy, but it can also lead to uneven temperatures and higher utility bills. Aluminum tape for ductwork is specifically engineered to seal joints, seams, and connections, preventing air leaks and ensuring that every bit of heated or cooled air reaches its destination.

Unlike traditional cloth or plastic tapes, aluminum foil tape is designed to withstand the temperature swings, moisture, and pressures found in HVAC environments. Its durable aluminum backing and long-lasting adhesive form a secure barrier that stands up to daily wear and tear.

Correctly applying hvac aluminum tape isn’t just about covering up cracks—it’s about ensuring system integrity. Here’s how it works:

Getting the most out of aluminum tape means following a few key steps:

By following these simple guidelines, you’ll notice a significant improvement in your HVAC system’s performance and lifespan.

Understanding the importance of proper sealing is just the start. Next, we’ll explore how aluminum tape’s strengths extend beyond ductwork, supporting insulation, repairs, and more throughout your home or business.

When you think of aluminum tape, HVAC ductwork might immediately come to mind. But have you ever wondered how this tape performs outside the world of heating and cooling? Let’s look at the broader applications—where its durability, thermal resistance, and waterproof properties make it a problem-solver for insulation, repairs, and sealing in countless scenarios.

Imagine you’re installing insulation panels in a wall or attic. Even the smallest gap between panels can compromise your home’s energy efficiency. This is where aluminum insulation tape steps in. Its robust, heat-resistant construction makes it ideal for joining insulation boards, closing seams, and ensuring a continuous thermal barrier. By sealing gaps, you help the insulation retain heat and block drafts—making your system more efficient and your space more comfortable. Plus, the tape maintains its hold even when exposed to heated surfaces, unlike adhesives that deteriorate at high temperatures.

Ever had to fix a leaky pipe or patch a metal surface exposed to the elements? Aluminum tape waterproof solutions are designed for just these challenges. Take, for example, the Nashua 361-11 Waterproofing Repair Tape: its aluminum foil backing and butyl rubber adhesive form a permanent, flexible seal that stands up to water, heat, and sunlight. This kind of tape is often used for:

What’s impressive is the tape’s ability to conform to irregular surfaces and maintain adhesion over time, even in extreme temperatures or fluctuating weather.

For larger-scale commercial or industrial projects, combining high-quality aluminum tape with advanced aluminum profiles ensures both energy efficiency and structural strength. For instance, when securing insulation around pipes or patching metal surfaces in a manufacturing facility, it’s not just about the tape—it’s also about the underlying structure. This is where engineered aluminum profiles, like those from Shengxin Aluminum, come into play. These profiles offer precision, corrosion resistance, and compatibility with a wide range of insulation and sealing materials.

By leveraging both advanced tape and engineered profiles, you get longer-lasting, more reliable insulation and waterproofing—whether you’re working on a high-rise, a factory, or a custom home.

In short, aluminum tape’s versatility goes far beyond ductwork. From patching leaks to creating vapor barriers and partnering with high-performance profiles, it’s a go-to for anyone seeking lasting results in insulation and repairs. Next, we’ll help you navigate the world of leading tape brands—so you can match the right product to your project’s demands.

Ever stood in the tape aisle, staring at rows of silver rolls, and wondered, “Which aluminum tape is really the best for my project?” With options like 3M aluminum tape and other high-performance brands, making the right choice can feel overwhelming. But it doesn’t have to be. Let’s break down how to select the best aluminum tape by focusing on what matters most: your application, the tape’s key specs, and how top brands stack up side by side.

When you see the name 3M, you probably think of reliability. 3M’s aluminum tapes are trusted by professionals for their flame resistance, strong adhesives, and ability to withstand extreme temperatures and humidity. They’re engineered for demanding jobs—think HVAC duct sealing, industrial insulation, or EMI shielding in electronics. Brands like 3M offer:

But how do you know which specific tape is the right fit for your job? That’s where understanding the specs comes in.

Imagine you’re sealing a duct in a freezing attic, or patching a pipe in a humid crawlspace. The best aluminum tape for each job depends on several factors:

By matching these specs to your project’s needs, you’ll get a tape that not only sticks—but lasts.

To help you make an informed decision, here’s a side-by-side comparison of leading aluminum tapes from 3M and other trusted brands, based on published technical data:

| Brand / Model | Adhesive Type | Thickness (mils) | Temp Range (°F) | Tensile Strength (lbs/in) | Best For |

|---|---|---|---|---|---|

| 3M 425 | Synthetic Acrylic | 4.6 | -65 to 300 | 30 | General HVAC, EMI/RFI Shielding, Flame Resistance |

| 3M 3340 | Acrylic | 3.9 | -40 to 300 | 29 | UL 181 HVAC Duct Sealing, High Strength |

| Shurtape AF-099 | Acrylic | 4.1 | Not Listed | 33 | UL 181 HVAC Ducts, High Adhesion |

| Nashua 361-11 | Butyl Rubber | 11 | 40 to 200 | 20 | Waterproof Repairs, Outdoor Sealing |

| Duck Brand Waterproofing | Butyl Rubber | 17 | -20 to 200 | 25 | Roof & Gutter Repairs, Waterproofing |

Still not sure? Here are a few quick tips:

Choosing a reputable tape brand is only part of the equation. For professional results—especially in commercial or industrial projects—pairing high-quality tape with precision-engineered aluminum profiles ensures energy efficiency, durability, and a clean finish. Leading manufacturers like Shengxin Aluminum deliver the advanced profiles that make the most of your chosen tape, helping you achieve lasting performance and structural integrity.

Now that you know how to select the right aluminum tape for your needs, let’s move on to where to buy it and what to look for on the packaging to guarantee you’re getting the best value and performance.

Ever found yourself in the hardware aisle at Home Depot or Lowe’s, staring at a wall of silver rolls, and wondering which aluminum tape is right for your project? With so many options, it’s easy to feel overwhelmed. Whether you’re shopping for aluminum tape home depot or comparing brands at Lowe’s, knowing what to look for can save you time and ensure your project’s success.

First, consider what you need the tape for. Are you patching a leaky pipe, sealing insulation, or working on ductwork? Here’s how to distinguish between the two main categories you’ll find at major retailers:

Before adding a roll to your cart, take a moment to check the packaging for these key details. This quick checklist ensures you get a tape that matches your needs—no matter if you’re shopping at Home Depot, Lowe’s, or Walmart:

| Feature | Why It Matters |

|---|---|

| UL Code (e.g., UL 181A-P or UL 181B-FX) | Indicates compliance with safety and performance standards for HVAC systems. |

| Adhesive Type (Acrylic, Silicone, Butyl) | Acrylic is good for general use and weather resistance; silicone excels in high-heat; butyl is best for waterproofing and flexibility. |

| Foil Thickness | Thicker foils offer greater durability and puncture resistance; thinner foils are more flexible for tight corners. |

| Temperature Rating | Ensures the tape will perform in your specific environment—check both minimum and maximum limits. |

| Release Liner | Makes application easier, especially for long runs or tricky surfaces. |

| Moisture/Chemical Resistance | Look for this if you’re working in damp or harsh environments. |

With this checklist in hand, you’ll be able to confidently select the best aluminum tape for your needs—whether you’re sealing HVAC ducts, patching insulation, or tackling creative DIY projects. Next, we’ll uncover some of the more specialized uses for aluminum tape in electronics and repairs, so you can make the most of its unique properties.

Ever wondered why some DIY electronics enthusiasts reach for aluminum tape when modding a mechanical keyboard or tweaking a gaming mouse? It might sound surprising, but this versatile tape isn’t just for HVAC or insulation—it plays a vital role in electronics projects, especially when it comes to shielding and grounding.

Picture this: you’re customizing a mechanical keyboard to achieve the perfect sound signature or modifying a mouse for better performance. Beyond switches and keycaps, savvy modders know that managing electrical noise and interference is crucial for reliable operation. That’s where aluminum tape comes in. Its conductive properties make it an accessible, cost-effective solution for:

Let’s get specific. If you’re searching for the best aluminum tape to mod mouse or keyboard, you’ll want a tape with a conductive adhesive. This ensures electrical continuity between overlapping layers, which is essential for effective EMI shielding. For instance, 3M’s conductive aluminum foil tape is widely used in professional electronics for its malleability, strong bond, and ability to conform to irregular surfaces.

Common applications include:

It’s important to note that not all tape mods are created equal. For example, in keyboard modding, non-conductive tapes (like painter’s tape) are often used for sound tuning, while aluminum tape EMI shielding is specifically for electrical performance (source). Always check that the adhesive is conductive if shielding is your goal.

In summary, aluminum tape is a secret weapon for electronics modders—providing EMI shielding, grounding, and even a bit of heat management without the hassle of soldering or bulky enclosures. Next, we’ll see how aluminum’s role expands into lighting, with specialized channels and profiles for professional LED tape installations.

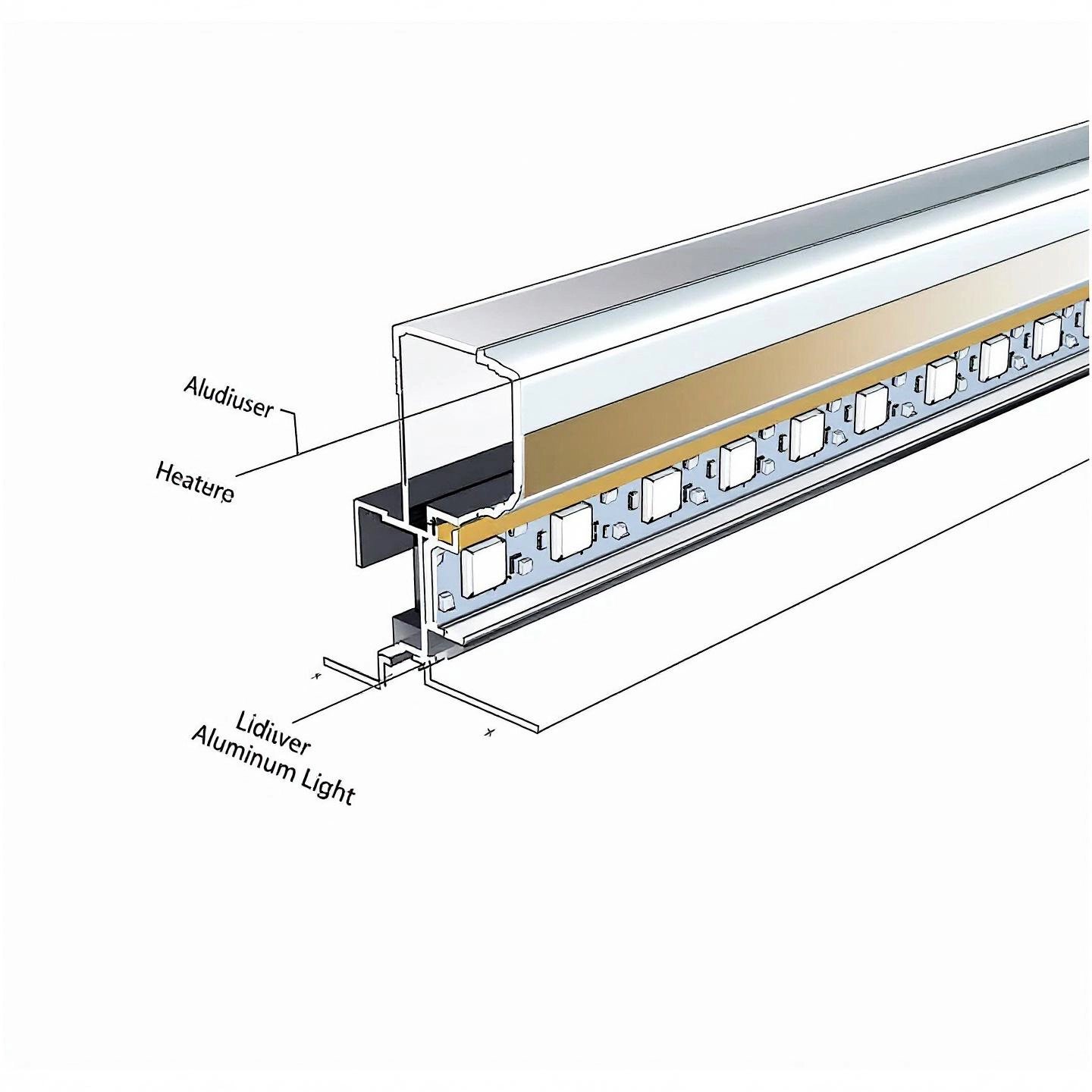

When you install LED tape lights, have you ever noticed uneven brightness, visible hot spots, or even premature failure due to heat? These common issues often arise when LED strips are mounted directly onto surfaces without extra support. That’s where the aluminum channel for led tape light becomes an essential part of any professional lighting project.

Imagine transforming a simple LED strip installation into a sleek, durable, and visually stunning lighting feature. Aluminum channels—also called LED aluminum profiles or extrusions—do just that. While not adhesive tape themselves, these components act as the backbone for your LED tape lights, providing:

Choosing the right led tape light aluminum profile depends on your installation needs. Here are the most common styles:

All styles typically include mounting hardware and a diffuser lens, making installation straightforward and results predictable.

Why does heat dissipation matter so much? Without it, LEDs can lose brightness, shift color, or fail prematurely. Aluminum’s excellent thermal conductivity ensures efficient heat transfer away from the strip, safeguarding your investment and maintaining consistent light output.

"Aluminum profiles act as heat sinks, dissipating heat away from LED strips to prevent overheating. This improves performance, maintains consistent light output, and ensures a longer lifespan for your LEDs."

For large-scale or custom lighting installations, the quality of your aluminum profiles is just as important as the LED strips themselves. High-precision extrusions ensure perfect alignment, seamless joins, and compatibility with a wide range of lighting designs. This is where expertise matters.

Manufacturers like Shengxin Aluminum specialize in producing industrial-grade LED aluminum profiles that meet strict tolerances for both structural strength and visual appeal. Their advanced manufacturing capabilities allow for custom shapes, finishes, and treatments—ideal for architectural, retail, or creative lighting projects where performance and aesthetics go hand in hand (reference).

In summary, using the right aluminum channel for LED tape light installation is the secret to achieving professional results—combining efficient heat management, protection, and a polished appearance. By partnering with trusted suppliers like Shengxin Aluminum, you can take your lighting projects to the next level, ensuring both beauty and long-term reliability.

Curious about how to securely fasten profiles or other aluminum components? Next, we’ll guide you through the basics of tapping screws into aluminum for clean, secure installations.

When you need to fasten aluminum profiles or install LED channels, have you ever wondered how to get a strong, clean joint—without cracking or stripping the metal? The answer often lies in using self tapping screws for aluminum. These specialized fasteners can turn a tricky job into a straightforward, reliable connection. But tapping aluminum the right way takes more than just grabbing a screw and a drill. Let’s break down exactly how to do it for professional results.

Aluminum is lightweight and easy to shape, but it can be surprisingly delicate when it comes to fastening. Regular screws may loosen over time or even damage the material, especially in applications where vibration is common. Self-tapping screws are designed with sharp, drill-like tips and continuous threads, allowing them to cut their own path through the metal—eliminating the need for separate drilling and tapping steps (source). This makes them ideal for joining aluminum parts quickly and securely, whether you’re building furniture, mounting lighting channels, or assembling enclosures.

With the right approach, tapping aluminum becomes a routine task that delivers strong, lasting connections—whether you’re finishing up a lighting project or assembling custom enclosures. Next, we’ll wrap up with a summary of aluminum tape’s versatility and how choosing quality materials ensures safety and durability across all your projects.

When you look back at the many ways aluminum tape can be used, it’s easy to see why it’s a staple for professionals, hobbyists, and repair experts alike. But what truly sets this material apart? Let’s recap its remarkable versatility and why making the right choices—both in tape and supporting materials—matters for every project.

From the start, we’ve seen that aluminum tape applications span far beyond a single trade or task. Imagine you’re sealing HVAC ducts, patching a leaky roof, shielding sensitive electronics, or even mounting LED lighting—aluminum tape adapts to each scenario, reliably delivering:

What ties these uses together is not just the tape’s physical properties, but its ability to solve real-world problems efficiently—saving time and preventing costly damage or energy waste.

But here’s an important question: Are all aluminum tapes and profiles created equal? The answer is no. Selecting the right tape for each application—considering adhesive type, thickness, and certification—directly impacts safety, efficiency, and durability. Likewise, pairing your tape with quality aluminum profiles ensures structural integrity and performance, especially in demanding environments like large-scale construction or advanced lighting installations.

Imagine the difference between a quick fix that fails and a professional solution that stands the test of time. The latter always starts with quality materials.

When embarking on your next project—whether it’s a home repair, an industrial upgrade, or a creative DIY build—consider the value of sourcing materials from reliable suppliers. Companies like Shengxin Aluminum bring decades of expertise in engineering quality aluminum profiles for every application, supporting your work with precision and consistency.

In the end, aluminum tape’s enduring popularity comes down to its adaptability and the confidence it brings to every task. By choosing the right products and partners, you can ensure safety, efficiency, and a job well done—no matter how complex or creative your vision may be.

Ready to take on your next project? Start with proven materials and trusted expertise—and let the versatility of aluminum tape and profiles unlock new possibilities for you.

Aluminum tape is commonly used for sealing, insulating, and repairing in HVAC systems, construction, electronics, and automotive applications. Its moisture, heat, and chemical resistance make it ideal for creating airtight seals on ductwork, joining insulation panels, patching metal surfaces, providing EMI/RFI shielding in electronics, and waterproofing repairs in various environments.

Yes, foil tape and aluminum tape generally refer to the same product: an adhesive tape with a thin aluminum foil backing. Both types are designed for similar uses, including insulation, ductwork, and shielding, offering durability, thermal conductivity, and resistance to moisture and chemicals.

Aluminum tape is more durable and better suited for HVAC and high-temperature applications compared to standard duct tape. While duct tape is versatile for general repairs, aluminum tape maintains its integrity under heat, moisture, and chemicals, making it the preferred choice for permanent, code-compliant sealing in HVAC and insulation projects.

Yes, aluminum tape is designed to be waterproof. Its aluminum foil backing and strong adhesive form an effective barrier against water and vapor, making it suitable for patching leaks, sealing insulation, and outdoor repairs where moisture resistance is essential.

Select aluminum tape based on the application's temperature range, adhesive type (acrylic, silicone, or butyl), thickness, and certifications such as UL 181 for HVAC. For professional results, pair high-quality tape with precision-engineered aluminum profiles from trusted manufacturers like Shengxin Aluminum to ensure optimal performance and durability.

online service

online service 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360