When you picture a trailer for hauling gear, appliances, or landscaping equipment, you might wonder: what sets an aluminum utility trailer apart from the rest? Simply put, it’s a versatile, open-bed trailer designed primarily from aluminum alloys instead of steel. These alloys combine aluminum with other metals to boost strength, so you get a trailer that’s both lightweight and durable. Most aluminum utility trailers use extruded frames and decks, which means the metal is shaped for maximum rigidity without unnecessary weight.

Why does this matter? Imagine loading up a riding mower or moving a stack of lumber. The lighter the trailer, the more you can haul before hitting your vehicle’s tow limit. Plus, aluminum’s natural resistance to rust means less time on maintenance and more time getting jobs done. Typical deck sizes range from 5x8 feet (great for household moves) to 7x14 feet (ideal for landscaping crews or powersports). GVWR (Gross Vehicle Weight Rating) for these trailers often spans 2,000–3,000 lbs for single-axle models, giving plenty of flexibility for most personal and light commercial uses. For example, a 6x10 aluminum trailer often offers enough space and payload for multiple ATVs or a week’s worth of lawn care work.

Sounds complex? Let’s break it down in real-world terms. Steel trailers are known for their brute strength and lower upfront cost, but they’re heavier and prone to rust, especially if you’re driving on salted winter roads or hauling corrosive materials. Aluminum trailers, on the other hand, are lighter and naturally corrosion-resistant, so they hold up better in wet climates or for those who store their trailer outdoors. While steel might be the go-to for heavy-duty construction, most homeowners, landscapers, and hobbyists find that aluminum’s blend of strength and weight savings is a better fit for everyday hauling needs.

| Deck Size | Base Weight (Aluminum) | Base Weight (Steel) | Estimated Fuel Savings* |

|---|---|---|---|

| 5x8 | ~600 lbs | ~900 lbs | Up to 10% |

| 6x10 | ~700 lbs | ~1,100 lbs | Up to 12% |

| 6x12 | ~800 lbs | ~1,250 lbs | Up to 15% |

| 7x14 | ~1,000 lbs | ~1,650 lbs | Up to 18% |

*Fuel savings estimates based on typical towing scenarios. Actual results may vary by vehicle and load.

Less trailer weight means more payload headroom and easier towing.

Imagine you’re a homeowner moving a new refrigerator, or a landscaper loading up mowers and trimmers for a busy week. With an aluminum trailer, you get a rust-resistant, lightweight utility trailer that’s easy to hitch, tow, and store. Powersports enthusiasts—think ATVs, motorcycles, or side-by-sides—also benefit from the lighter curb weight and corrosion resistance, especially if the trailer sees a lot of road salt or rain.

In 2025, the demand for aluminum utility trailers continues to rise as buyers look for lower fuel costs, less maintenance, and longer service life. Whether you need a compact 5x8 for weekend projects or a spacious 6x12 aluminum utility trailer for business, there’s a size and configuration to fit your needs.

Ready to dive deeper? Next, we’ll help you match deck size and axle setup to your specific loads and storage space—see the upcoming section for practical sizing tips!

When it comes to selecting an aluminum utility trailer, one of the first questions to ask is: what do you need to haul most often? Sounds simple, but the answer shapes everything from deck length to axle count. Imagine you’re moving a riding mower, a stack of lumber, or a pair of ATVs—each load calls for a different deck size and payload rating. Here’s a quick reference to help you match common cargo to the right trailer dimensions:

| Cargo Type | Recommended Deck Size | Typical Curb Weight | Expected Payload |

|---|---|---|---|

| ATV (single) | 5x8 | ~600 lbs | 1,200–1,400 lbs |

| Lawn Tractor | 6x10 | ~700 lbs | 1,500–1,700 lbs |

| Building Materials (pallets, lumber) | 6x12 | ~800 lbs | 1,800–2,200 lbs |

| Multiple ATVs or UTV | 7x14 | ~1,000 lbs | 2,500–3,000 lbs |

For most residential and light commercial tasks, a 6x10 aluminum trailer or 6x12 aluminum trailer will comfortably fit mowers, building supplies, or a pair of recreational vehicles. If you’re considering a 5x10 aluminum trailer for lighter jobs, double-check your largest expected load and add a bit of margin—you’ll thank yourself later.

Once you’ve dialed in the right deck size, the next decision is axle configuration. Should you go with a single axle or upgrade to a tandem axle aluminum utility trailer? Here’s how they stack up:

For example, a 7x14 aluminum utility trailer with tandem axles can accommodate larger, heavier loads—think multiple ATVs or heavy building materials—while also reducing bounce and tire wear on rough roads. However, single axle trailers excel in tight quarters and are easier to park, especially around the home or in urban settings. Maintenance is also simpler with fewer tires and brakes to service, but tandem axles pay off with smoother towing and better safety under load.

Worried about where your trailer will live when not in use? Before you order that 7x14 or 6x12 aluminum utility trailer, take a few quick measurements. The average single garage door is about 9 feet wide and 7 feet tall, so most trailers up to 6 feet wide and 12–14 feet long will fit in a typical garage or driveway. If you’re short on storage, a 5x10 aluminum trailer or 6x10 aluminum trailer is easier to tuck away and maneuver around corners.

Always measure twice—gate width, garage depth, and turning radius—before choosing your trailer size.

In summary, the right aluminum utility trailer size and axle setup depends on your biggest load, storage space, and how often you’ll tow. Next up, we’ll walk through towing compatibility and safety, so you can hit the road with total confidence.

Ever wondered why your trailer feels unstable or why connecting it sometimes seems trickier than it should? Much of it comes down to matching your tow vehicle’s hitch class and ball size to your aluminum utility trailer. For most 5x8 aluminum utility trailer and 6x10 aluminum utility trailer models, you’ll typically encounter couplers designed for 1-7/8", 2", or 2-5/16" hitch balls. The right match ensures a secure connection and prevents dangerous disconnects on the road. Always check your trailer’s manual for the manufacturer’s recommended hitch class and ball size—don’t just guess based on appearance. If you’re unsure, a quick check with your local trailer dealer or referencing SAE J684 coupling standards is a smart move.

What about stopping power? Brake systems are a must for heavier aluminum trailer utility setups, especially as you move up in size or payload. According to federal guidelines (FMCSA Brake Regulations), all brake components must be installed and maintained for safe, reliable stopping. Trailers with a gross vehicle weight rating (GVWR) over 3,000 lbs—think larger 6x10 utility trailer weight or even a 10k utility trailer—are usually required to have brakes on all wheels. Single-axle trailers may use electric drum brakes, while tandem axle models often feature brakes on both axles for added safety.

For commercial and heavier-duty applications, air or hydraulic brakes may also require additional checks, including warning signals and emergency activation features. Always consult your trailer’s manual and DOT/NHTSA guidelines for specifics.

Why does your trailer sway or feel unpredictable? The answer is often tongue weight and load balance. Tongue weight is the downward force your trailer exerts on the hitch. For safe towing, it should be 10–15% of the trailer’s total loaded weight. For example, if your loaded 6x10 aluminum utility trailer weighs 2,000 lbs, the tongue weight should be 200–300 lbs. Too little, and you risk sway; too much, and steering and braking suffer.

| Pre-Trip Safety Checklist | |

|---|---|

| Hitch height | Trailer should be level when hitched |

| Ball & coupler connection | Fully engaged and locked |

| Safety chains | Crossed and securely attached |

| Breakaway battery | Charged and tested |

| Lights | Brake, turn, and running lights all working |

| Tire pressure | Set to manufacturer’s specs |

| Lug nut torque | Checked and tightened |

Set tongue weight to 10–15% of total trailer weight, and always re-check after loading for a safe, stable tow.

Sounds like a lot? Once you develop a simple routine, these steps become second nature—especially for owners of lightweight utility trailers who want maximum safety with minimum hassle. For more in-depth advice on adjustable hitches and fine-tuning your setup, check out this comprehensive hitch guide.

Now that you know how to set up your aluminum trailer utility for safe towing, the next step is choosing options and upgrades—like ramps, tilt decks, and decking—that fit your hauling style. Let’s explore how to make your trailer work even harder for you in the next section.

Ever found yourself wrestling with a heavy mower or ATV and wondering if there’s a smoother way to load your trailer? The right options and add-ons can turn a basic small utility trailer aluminum build into a true workhorse—while the wrong ones can add weight, cost, or hassle. Let’s break down the top choices, from loading solutions to decking, so you can invest where it counts and skip what you don’t need.

When it comes to loading your utility trailer aluminum, the two most common options are ramp trailers and aluminum tilt trailers. Each has its own strengths, and the best fit depends on your cargo, frequency of use, and storage situation.

| Option | Typical Price Range | Added Weight | Maintenance Notes |

|---|---|---|---|

| Ramp Trailers | $5,000–$10,000 | +80–100 lbs (ramps) | Check ramp hinges, store ramps dry |

| Aluminum Tilt Trailer | $9,000–$20,000 | +60–120 lbs (tilt system) | Annual hydraulic or mechanical checks |

| Aluminum Deck Trailer | $8,000–$15,000 | Minimal (aluminum extrusions) | Occasional cleaning, inspect joints |

Choose the lightest option that meets your loading frequency and cargo type.

For example, landscapers loading mowers several times a day will appreciate the speed and convenience of an aluminum tilt trailer, while a homeowner who moves heavy equipment a few times a year may find ramp trailers more cost-effective.

The right deck and sidewall setup protects your cargo and extends the life of your aluminum trailers utility. Here are the top decking options:

For sidewalls, consider removable side kits for hauling mulch, stone, or loose materials. Aluminum extrusions for sides provide corrosion resistance and keep weight down, while steel or wood can be heavier but sometimes less expensive.

Want a deck that lasts? An aluminum deck trailer with extruded planks is a top pick for small utility trailer aluminum builds that see year-round use.

Accessorizing your trailer is about more than just convenience—it’s about safety and protecting your investment. Here’s what to consider:

Smart upgrades like these help your utility trailer aluminum setup last longer, run safer, and keep your gear protected, whether you’re on the job or off the beaten path.

With the right mix of ramps or tilt, durable decking, and essential accessories, your aluminum trailers utility can adapt to any job. Next, we’ll show you how to keep your investment in top shape with a simple, effective maintenance routine.

Ever wondered why some aluminium utility trailers look and perform like new years down the road while others show early signs of wear? The answer is a smart, simple maintenance routine. Whether you own a compact aluminum 5x8 utility trailer or a larger 12 aluminum utility trailer, a little care goes a long way—protecting your investment, ensuring safety, and preserving resale value. Let’s break down the essentials so you can keep your trailer in top shape with confidence.

Sounds complex? It’s actually straightforward when you follow a schedule. Imagine heading out for a busy season of hauling, only to find a flat tire or a stuck coupler. Here’s how to avoid those headaches:

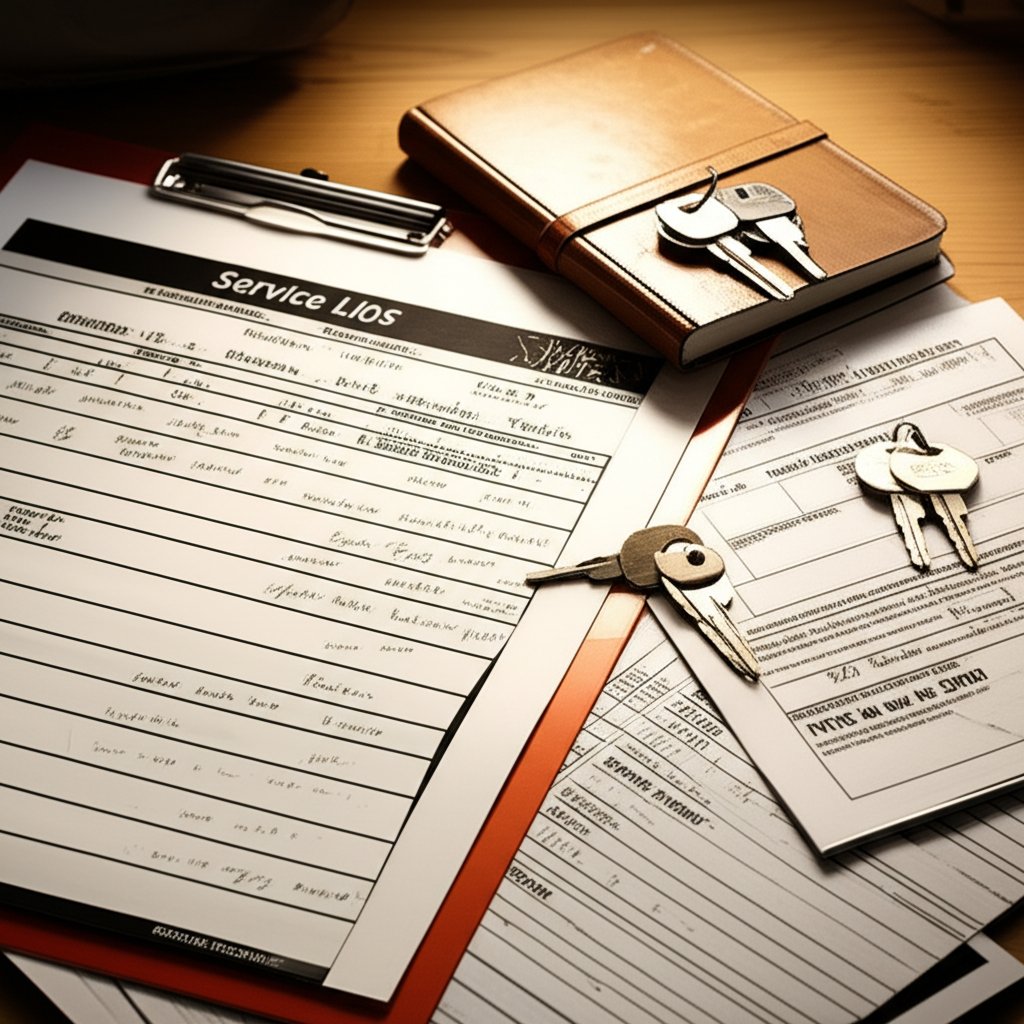

Document each service in a log—photos and receipts boost resale value and help you track wear over time.

One of the biggest perks of aluminium utility trailers is their resistance to rust, but that doesn’t mean cleaning is optional. Regular washing removes corrosive road salts and grime that can dull finishes or cause pitting. Here’s how to clean safely and keep your trailer shining:

| Cleaner Type | pH Range | Compatible Finishes |

|---|---|---|

| Mild soap (e.g., Tide, Ivory) | 6–8 | Painted, bare aluminum |

| Isopropyl alcohol | Neutral | Adhesive removal (spot use) |

| Commercial degreaser (Simple Green, Fantastic) | 7–9 | Stubborn grime (test first) |

| Bleach solution (for mold/mildew) | 7–8 | Painted surfaces (rinse well) |

Don’t forget to wash the undercarriage and wheels, especially after winter use. This simple habit keeps your aluminum 5x8 utility trailer or larger model looking great and prevents premature corrosion.

Even with the best care, you might spot a cracked weld, bent frame rail, or electrical issue. Not sure when to DIY or call in a pro? Here’s a quick guide:

Always follow your axle manufacturer’s documentation—especially for torque specs and brake service. For Dexter axles, refer to their official service manual.

Keeping up with maintenance doesn’t have to be overwhelming. With a simple schedule, safe cleaning habits, and prompt repairs, your aluminium utility trailers will deliver years of reliable, worry-free hauling. Next, we’ll break down the true costs of ownership—so you know exactly what to expect from purchase to resale.

When you start shopping for an aluminum utility trailer for sale, the first question that comes up is, "How much should I expect to pay?" The answer depends on deck size, features, and whether you’re buying new or used. For 2025, here’s a realistic breakdown to help you set your budget:

Options like tilt decks, aluminum decking, upgraded tie-downs, and LED lighting can add $500–$2,000 to the sticker price. Dealer fees, registration, and delivery may tack on another $200–$800 depending on your location.

Searching for aluminum utility trailers for sale near you? Prices may vary by region, but the above ranges offer a solid starting point for most buyers.

Upfront price is just one part of the story. Imagine you’re comparing an aluminum utility trailer for sale near me to a similar steel model—how do costs stack up over five years? Let’s break it down with real-world numbers:

| Aluminum Utility Trailer | Steel Utility Trailer | |

|---|---|---|

| Initial Price (6x12, new) | $5,000 | $3,800 |

| 5-Year Maintenance | $500–$2,600 | $720–$3,800 |

| Fuel Cost Impact* | Lower (6–12% savings) | Higher |

| Resale Value (after 5 years, typical condition) | $2,700–$3,500 | $1,200–$2,000 |

| Estimated TCO (5 years) | $2,000–$4,400 | $2,500–$5,600 |

*Aluminum trailers are up to 20% lighter, saving 6–12% on fuel per mile compared to steel.

Why does aluminum win on total cost? Lower maintenance (no rust repairs), better fuel efficiency, and higher resale value. Steel trailers may seem cheaper upfront, but you’ll likely pay more in repairs and lose value faster due to corrosion and appearance issues.

Ready to buy? Whether you’re browsing aluminum trailers for sale at a dealer or hunting for used aluminum trailers for sale online, a smart strategy can save you hundreds—or more. Here’s how to get the best deal:

Clean service records and documented upgrades can add real resale value—don’t underestimate the power of good paperwork.

Buying used? Look for signs of excessive wear, rust (on steel), or missing paperwork. Dealers may offer certified pre-owned options for peace of mind, but private sales can yield better prices if you know what to inspect. Always confirm title and registration requirements in your state before finalizing the deal.

Understanding the true cost of owning an aluminum utility trailer helps you make a confident, informed purchase—whether you’re eyeing new aluminum trailers for sale or evaluating used aluminum trailers for sale in your area. Next, we’ll guide custom builders and fleet buyers on sourcing the best aluminum extrusions for long-term durability and value.

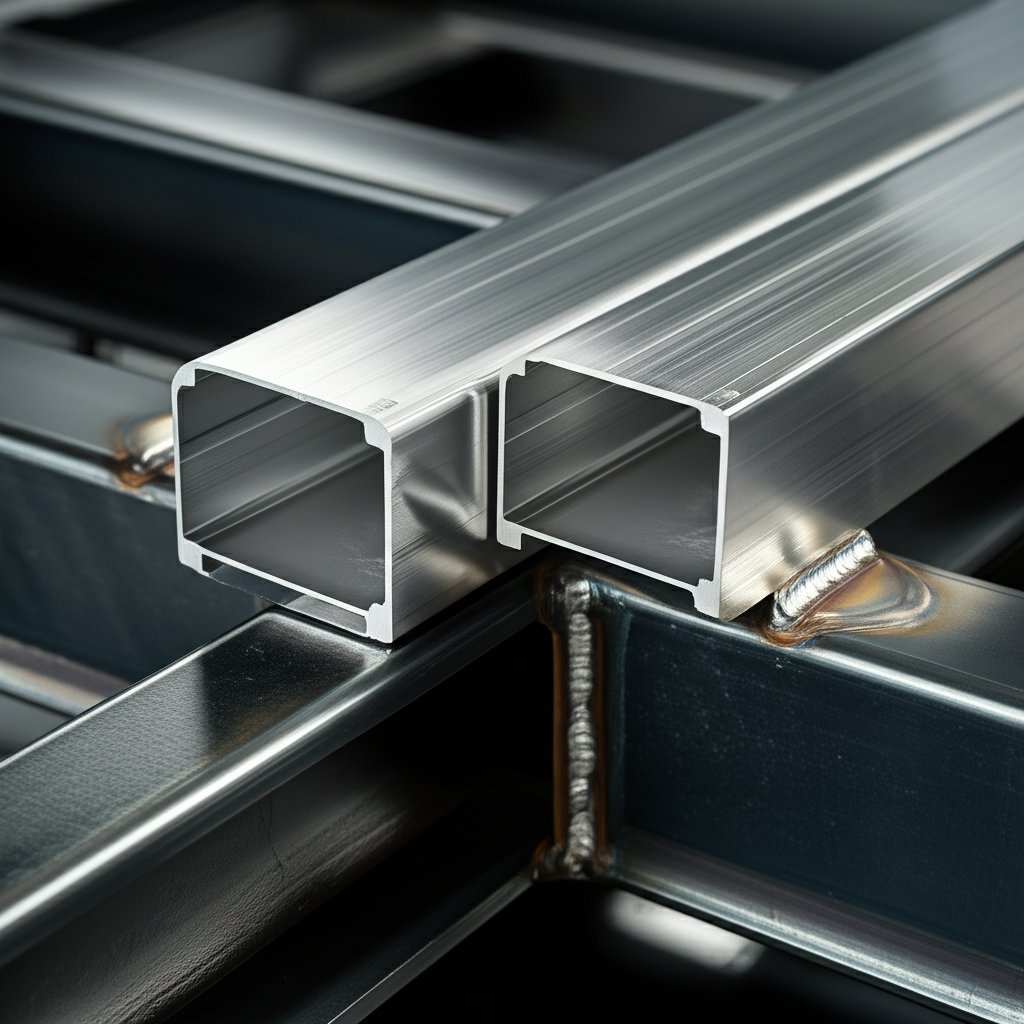

When you’re building or specifying a best aluminum utility trailer—whether it’s a compact 5 x 8 aluminum utility trailer for weekend use or a full fleet for commercial work—one decision makes all the difference: the quality of your aluminum extrusions. Sounds technical? Here’s why it matters. The frame, side rails, ramps, and decking of an aluminum utility trailer depend on extruded aluminum profiles for both structural integrity and weight savings. Choosing the right alloy and extrusion supplier is what separates a trailer that lasts from one that disappoints.

Aluminum extrusions are made by forcing heated aluminum through a die to create shapes with precise cross-sections. This process allows for lightweight, strong, and corrosion-resistant parts that are essential for keeping your trailer’s curb weight low and payload high. For example, 6xxx series alloys like 6061-T6 are common in trailer frames due to their excellent strength-to-weight ratio and good weldability.

Thinking of sourcing components for your next aluminum utility trailer build? Start by asking suppliers about their alloy selection, tempering processes, and available finishes. Not all aluminum utility trailer manufacturers offer the same expertise or quality control. Here’s a quick checklist to guide your supplier conversations:

For custom builds or large orders, you’ll want to verify that your supplier can consistently deliver straight, defect-free extrusions that meet your specs. Warpage and dimensional variance are common issues, especially for longer parts.

Lead time and minimum order quantity (MOQ) can make or break your project’s timeline and budget. Most established aluminum utility trailer manufacturers in China’s industrial clusters—like those in Zhejiang or Guangdong—offer competitive lead times and integrated supply chains. Tooling for new dies may take 30–50 days, with sample production in 15–30 days for standard profiles. Always confirm whether expedited sampling is available and what the cost premiums are.

Certifications matter too. Prioritize suppliers with ISO 9001 or CE marks for quality assurance. Some leading aluminum trailer brands partner directly with manufacturers holding these credentials to ensure consistency and compliance for aluminium cargo trailers and specialty builds.

| Supplier | Main Alloys | Certifications | Anodizing/Finishes | Lead Time | MOQ | Support |

|---|---|---|---|---|---|---|

|

Shengxin (aluminum extrusion profiles China) |

6000 series (6061, 6063) | ISO 9001, National/Industry | Anodizing, powder coating, wood grain | 30–50 days (tooling), 15–30 days (samples) | Negotiable | Full design & tech support |

| APEL Extrusions | 6000 series | ISO, Plant-specific | Anodizing, painting | Short (historically fast) | Flexible | North America focus |

| Foshan Kindle | 6061-T6, 6063 | ISO 9001, CE | Anodizing, powder coating | 30–45 days | 500–1,000 kg | Export expertise |

| Zhenjiang Swt Metal | 6061-T6 | ISO 9001 | Custom | 30–40 days | Negotiable | OEM/ODM |

| Qingdao Yiche Yiguan | 6061, 6063 | CE | Powder coating, custom | Rapid samples (1h reply) | Small batch | Quick response |

Quality extrusions are the backbone of every reliable aluminum utility trailer—don’t cut corners on your supplier vetting.

Whether you’re a fleet manager standardizing builds or a DIY enthusiast aiming for the best aluminum utility trailer possible, careful sourcing of extrusions and components pays off for years to come. Next, see how real buyers configure and use their trailers for maximum value and performance.

Ever wondered how real buyers put their aluminum utility trailer to work? Let’s dig into three case studies—each showing how different needs, trailer options, and maintenance choices add up to real savings, efficiency, and peace of mind. Whether you’re searching for aluminum utility trailers near me or planning to customize your own, these stories offer practical setups you can model for your next purchase.

| User Type | Deck Size | Axle Setup | Options | Weekly Miles | Outcomes |

|---|---|---|---|---|---|

| Homeowner | 6x10 | Single | Ramp, removable sides, LED lights | 25 | Easy appliance moves, low maintenance, strong resale |

| Landscaping Crew | 7x14 | Tandem | Tilt deck, side kit, tie-downs | 200 | Faster loading, 10–12% fuel savings, high uptime |

| Powersports Enthusiast | 6x12 | Single | Ramps, D-rings, spare tire mount | 60 | Safe ATV/UTV hauling, easy solo loading, holds value |

The right trailer setup pays you back with faster jobs, lower fuel costs, and strong resale—no matter if you’re a homeowner, business, or weekend adventurer.

As you can see, matching your trailer’s size, axle type, and features to your actual use—and keeping up with simple maintenance—delivers real-world savings and convenience. Whether you’re browsing aluminium utility trailers for sale or comparing 6x12 aluminum utility trailer near me listings, use these examples to guide your own configuration. Up next, we’ll wrap up with a handy decision checklist and resources to help you buy smarter and sell for more when the time comes.

Ready to take the leap and buy your aluminum utility trailer? Before you start comparing aluminum utility trailers for sale near me or sorting through aluminum trailer sales listings, it’s smart to run through a quick, actionable checklist. This way, you’ll avoid surprises and make sure your investment pays off for years to come. Imagine the confidence you’ll feel knowing you’ve checked every box, from budget to paperwork.

Thinking ahead to resale? Keeping the right documents can mean the difference between a quick, top-dollar sale and a drawn-out process. Whether you’re listing your aluminium utility trailer for sale or trading in at aluminum trailer sales near me, these records are your best friend:

| Document | Why It Matters |

|---|---|

| Title/Registration | Proves legal ownership and makes transfer easy |

| Service Log | Shows regular maintenance and boosts buyer confidence |

| Receipts | Documents repairs, upgrades, and parts |

| Photos (before/after) | Demonstrates condition and any improvements |

| Accessory Manuals | Helps new owner use and maintain options |

Documented maintenance and clean wiring are the top drivers of fast, high-value resale for any aluminum utility trailer.

Still have questions or want to compare options before making a decision? Here are some resources and next steps to help you move forward with confidence, whether you’re buying new, used, or planning a custom build:

As you wrap up your research, remember: your best aluminum utility trailer is the one that fits your needs, budget, and future plans. Use this checklist, keep your paperwork organized, and lean on trusted resources to make your purchase—and eventual resale—as smooth as possible.

Aluminum utility trailers offer significant weight savings, making them easier to tow and maneuver. They are naturally resistant to rust, resulting in lower maintenance needs and a longer lifespan, especially in wet or salty environments. Additionally, aluminum trailers typically retain higher resale value due to their durability and appearance.

Start by listing your typical loads and measuring the largest items you plan to haul. For lighter loads under 2,000 lbs, a single axle trailer like a 6x10 aluminum trailer is usually sufficient. For heavier or more frequent hauling, a tandem axle model offers greater stability and payload. Always consider your available storage space and ensure the trailer fits your garage or parking area.

Regularly check tire pressure, lights, and safety chains before each trip. Monthly, lubricate moving parts and clean the trailer to remove grime and salt. Annually, inspect and service wheel bearings, brakes, and fasteners. Use mild cleaners and avoid harsh chemicals to protect the aluminum finish. Document all maintenance in a service log to enhance resale value.

While aluminum trailers generally have a higher upfront cost, they often result in lower total cost of ownership. This is due to reduced fuel consumption from lighter weight, minimal rust-related repairs, and higher resale value. Over five years, many owners find aluminum trailers are more cost-effective than steel alternatives.

For custom aluminum utility trailer builds, sourcing high-quality extrusions is essential. Suppliers like Shengxin in China provide certified aluminum profiles suitable for frames, rails, and decking. Ensure your supplier offers mill test reports, proper surface treatments, and reliable lead times to guarantee strength and durability in your trailer.

online service

online service 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360