Wondering if you can powder coat aluminum? The answer is a resounding yes—when you follow the right steps, aluminum takes a powder coat finish exceptionally well. In fact, powder coating aluminum is one of the most effective ways to protect and beautify this versatile metal for both industrial and architectural applications.

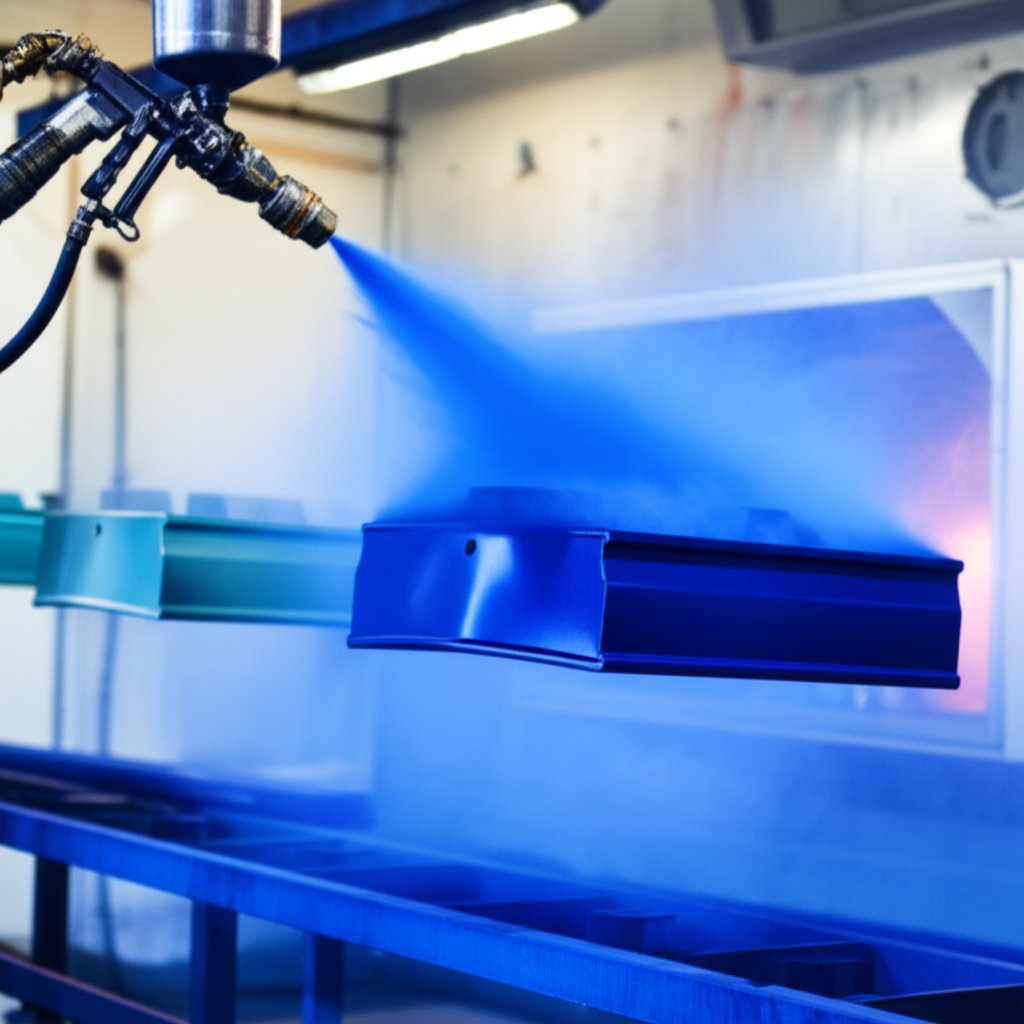

Powder coating is a dry finishing process where charged polymer particles are sprayed onto a grounded aluminum part. The powder adheres electrostatically and, when cured in an oven, melts into a continuous, durable film. This process delivers several clear advantages:

Real-world examples of powder coated aluminum include wheels, window frames, marine furniture, extrusions, signage, and playground equipment. Whether you’re specifying parts for architecture or manufacturing, aluminum powder coating delivers both protection and aesthetics that last.

Let’s break down how powder coating aluminum compares to other popular finishing methods:

| Finish Type | Durability | Color Options | Reparability | Cost per Year |

|---|---|---|---|---|

| Powder Coating | High (10–20 yrs outdoors) | Extensive | Moderate | Low |

| Liquid Paint | Moderate (2–5 yrs outdoors) | Extensive | Easy | Higher |

| Anodize | Very High (15–30 yrs+) | Limited (mainly metallics) | Difficult | Low/Moderate |

While anodizing offers unmatched wear and corrosion resistance, powder coating provides a thicker, more versatile finish with broader color choices and easier application for complex shapes. Paint is best for budget or DIY projects but falls short on longevity and protection.

Powder coating aluminum isn’t just possible—it’s often the best way to achieve long-term durability, vibrant color, and corrosion protection for your project. Proper pretreatment and adherence to industry standards are key to making the finish last.

As you continue, you’ll learn how to specify, pretreat, apply, and maintain aluminum powder coating to meet the highest standards in 2025. If you’ve been asking, “can aluminium be powder coated for my application?”—the answer is yes, with proven results across industries.

Ever wondered what actually happens between raw aluminum and that flawless, durable finish? The powder coating process steps for aluminum are precise, and every detail matters—especially if you want your finish to last for years, not just months. Let’s walk through exactly how to powder coat aluminum, from the first cleaning wipe to the final cure.

| Powder Chemistry | Film Thickness (µm) | Spray Voltage (kV) | Cure Temp (°C) | Cure Time (min) |

|---|---|---|---|---|

| TGIC Polyester | 60–80 | 50–90 | 180–200 | 10–15 |

| Epoxy | 60–100 | 50–80 | 160–190 | 10–20 |

| Fluoropolymer | 40–70 | 60–90 | 200–230 | 10–20 |

Adjust voltage, gun distance (typically 8–12 inches), and passes based on part geometry for best results. Thin-walled extrusions or intricate shapes may require lower voltage and closer gun placement to avoid the “Faraday cage” effect—where powder struggles to reach deep recesses.

How do you powder coat aluminum without missed spots or uneven coverage? Start with a steady hand and the right settings:

Pre-heating complex or heavy parts can also help powder wrap around edges and fill hard-to-reach spots, minimizing touch-ups.

Here’s where many powder coating process steps go wrong: it’s not about the oven air temperature, but the actual temperature of the aluminum itself. Use a metal-temp probe or thermocouple attached to the part—not just the oven display. Most powders require the aluminum to reach 180–200°C (356–392°F) and hold for 10–20 minutes, depending on the powder’s technical data sheet. Thicker or larger parts may need longer to reach the target temperature for powder coating throughout.

Always verify cure with a metal-temp probe and a solvent rub (such as MEK double rubs per the powder’s TDS) rather than relying on time alone. This ensures full cross-linking and maximum durability.

Signs of undercure include poor adhesion, dull finish, and reduced hardness. Overcure can cause discoloration or brittleness. Consistent, even heating is especially important for thin-walled or complex aluminum extrusions to avoid warping or uneven finish.

Understanding these powder coating process steps and dialing in the right temperature for powder coating is the foundation for a finish that lasts. Next, we’ll detail the pretreatment recipes that make powder stick—and stay—on aluminum, so you can avoid the most common causes of failure and maximize performance.

Ever prepped a surface, only to watch your beautiful finish peel or corrode months later? When it comes to powder coating aluminum, the hidden hero is always proper pretreatment. If you want your coatings for aluminum to last, every step before the powder hits the part matters just as much as the powder itself. Let’s break down exactly how to get aluminum ready for a finish that truly sticks—and stands up to the toughest environments.

Imagine you’re building a house: if the foundation is shaky, nothing on top will last. The same goes for aluminum surface preparation. Aluminum naturally forms a thin, stubborn oxide layer that’s great for corrosion resistance but terrible for powder adhesion. Without removing and controlling this oxide, your powder coat may flake, bubble, or fail early—especially in demanding outdoor or marine conditions.

Here’s a proven, job-shop-ready sequence for surface preparation for powder coating on aluminum. Each stage is designed to clean, etch, and chemically prepare the metal for maximum powder bond and corrosion protection. Use this as a reference for your own line or when specifying coatings for aluminum with your supplier.

| Step | Chemistry | Concentration | Temperature (°C) | Dwell Time (min) | Purpose |

|---|---|---|---|---|---|

| 1. Alkaline Clean | Mildly alkaline cleaner | 2–5% | 45–60 | 2–5 | Remove oils, dirt, and organic contaminants |

| 2. Rinse | City water, then DI water | — | Ambient | 1–2 | Remove cleaning residues |

| 3. Alkaline Etch | Sodium hydroxide | 10–50 g/L | 40–60 | 1–3 | Micro-etch surface, remove oxide, create matte texture |

| 4. Desmut/Deoxidize | Nitric or mixed-acid with fluoride | Nitric 15–25% + ammonium bifluoride 1–3% | Ambient–30 | 1–3 | Remove smut, intermetallics, prep for conversion coat |

| 5. Rinse | City + DI water | — | Ambient | 1–2 | Eliminate acid and particulate residues |

| 6. Conversion Coating | Chromate (Alodine/Iridite) or non-chrome zirconium/titanium | Per supplier TDS (e.g., 0.05–0.2% active for non-chrome) | Ambient | 1–3 (chromate), 0.5–2 (non-chrome) | Form corrosion-resistant, paintable layer |

| 7. Final DI Rinse | Deionized water | — | Ambient | 1–2 | Remove soluble residues, control conductivity (≤30 µS/cm) |

| 8. Dry | Hot air | — | 80–110 | Until dry | Prevent water spots, ready for coating |

Think of conversion coating as the “primer” for coatings for aluminum. Chromate systems (like Alodine or Iridite) have long been the gold standard for corrosion resistance and paint adhesion, especially in aerospace and marine applications. However, non-chrome zirconium or titanium nano-coatings are now widely used for environmental and regulatory reasons. Both types create a thin, invisible film that dramatically improves powder adhesion and corrosion protection, but always match your choice to the application and required performance.

Not all aluminum alloys behave the same. For example, high-copper alloys may need adjusted etch or deoxidizer times to avoid pitting or smut. Too short an etch can leave behind oxides; too long can expose more intermetallics and increase corrosion risk. Always target a uniform, water-break-free surface—this is your visual cue that the metal is ready for conversion coating.

Rinsing may sound simple, but it’s where many failures start. Use city water by deionized water to keep conductivity low and prevent surface contamination. Long transfer times between tanks, dirty racks, or poorly maintained rinse baths can lead to streaks, blotches, or powdery coatings. For drying, keep the temperature between 80–110°C—too hot can crack the conversion layer, too cold can trap moisture and cause salt spray failures.

Conversion coat shall be non-chrome zirconium per supplier TDS, applied to yield a uniform, invisible film; final rinse DI conductivity ≤30 µS/cm; water break-free surface prior to coating.

Perfecting your aluminum surface preparation and powder coating pretreatment is the most effective insurance policy for a long-lasting, beautiful finish. Next, let’s look at the powder chemistries that build on this solid foundation for even greater performance.

Ever looked at a row of powder coated aluminum parts and wondered why some finishes outlast others—shining bright in the sun, resisting chips, or shrugging off harsh chemicals? The secret is in the chemistry. Choosing the right powder coat finish for your aluminum project means balancing environment, performance, and looks. Here’s how you can match the right aluminium powder coating to your needs, whether you’re building a downtown facade, marine railing, or a set of sleek office furniture.

Not all powder coating finishes are created equal. Each chemistry brings its own strengths—and limitations. Imagine you’re specifying a finish for outdoor railings versus lab benches; your choice will directly impact durability, color retention, and maintenance.

| Chemistry | Film Thickness (µm) | Cure Temp (°C) | UV Resistance | Chemical Resistance | Common Uses |

|---|---|---|---|---|---|

| TGIC Polyester | 60–80 | 180–200 (10–15 min) | Excellent | Good | Architectural, outdoor furniture, windows |

| Non-TGIC Polyester | 60–80 | 180–200 (10–15 min) | Excellent | Good | Batch production, architectural panels |

| Super Durable Polyester | 60–80 | 180–200 (10–15 min) | Superior | Good | Façades, cladding, high-UV exteriors |

| Epoxy | 60–100 | 160–190 (10–20 min) | Poor | Excellent | Indoor, industrial, lab equipment, primer |

| Hybrid (Epoxy-Polyester) | 60–80 | 160–190 (10–15 min) | Moderate | Very Good | Office furniture, shelving, interior fixtures |

| Fluoropolymer (FEVE/PVDF) | 40–70 | 200–230 (10–20 min) | Outstanding | Very Good | Coastal, extreme UV, high-end architecture |

| Polyurethane | 50–100 | 180–200 (10–15 min) | Very Good | Excellent | HVAC, automotive, outdoor hardware |

For most exterior aluminum, TGIC or super durable polyester is the go-to for long-term UV and weather resistance. If you’re coating parts for harsh chemical environments—like lab benches or machinery—epoxy or polyurethane powder paint is a better fit, but keep those indoors or use them as a primer under a UV-stable topcoat. Hybrid powders strike a balance for interior fixtures. And for the ultimate in fade resistance and gloss retention, fluoropolymer powders (like FEVE or PVDF) are unmatched, especially in coastal or sun-intense environments.

Ever noticed a powder coat finish that looks thick but chips easily, or one that fades too quickly? Getting the right film thickness and cure is critical. For most aluminium powder coating, a film thickness of 60–80 microns is the sweet spot—thick enough for protection, thin enough for flexibility and aesthetics. Architectural and outdoor parts should always hit this range, while heavy-wear industrial parts may go up to 100–150 microns for added durability.

Cure schedules matter just as much. Polyester powders typically require 180–200°C at the part for 10–15 minutes; fluoropolymers may need higher temps (200–230°C). Under-curing can lead to soft, easily damaged finishes, while over-curing risks discoloration or brittleness. Always check the powder manufacturer’s technical data sheet (TDS) for the exact window, and use a metal temperature probe for accuracy.

Sounds complex? It’s easier than you think. Reviewing the TDS (technical data sheet) for your chosen powder gives you everything you need to get a professional result. Here’s what to look for:

When in doubt, review TDS from trusted powder and pretreatment suppliers. Here are a few reputable brands to consider:

Remember, the right aluminium powder coating is your insurance against fading, corrosion, and early failure. If you’re unsure which chemistry fits your project, consult the TDS and ask your supplier for test results on real-world aluminum parts. Next, we’ll dive into the industry standards and testing that prove your finish is built to last.

When you specify powder coated aluminum, how can you be sure the finish will truly last? The answer: rigorous industry standards and proven test methods. These standards turn lab results into real-world confidence—whether you’re coating windows for a high-rise or railings for a coastal boardwalk. Let’s break down the essential benchmarks every buyer, engineer, and applicator should know.

Imagine receiving a batch of powder coated parts—how do you know the adhesion, gloss, and durability are up to par? That’s where ASTM International standards come in. They provide clear, repeatable tests for every critical property:

| Test Standard | What It Measures | Typical Target for Aluminum |

|---|---|---|

| ASTM D3359 | Cross-hatch adhesion | 4B–5B (no or minimal coating removal) |

| ASTM D523 | 60° gloss level | Per product spec (e.g., 30 ± 5 GU for matte) |

| ASTM B117 | Neutral salt spray (corrosion resistance) | 1,000–1,500 hours to scribe, ≤2–3 mm creepage |

| ASTM D3363 | Pencil hardness | H–2H (scratch resistance) |

These tests are easy to perform and form the backbone of powder coatings quality control. For example, the cross-hatch adhesion test (ASTM D3359) uses a simple grid and tape method to check if the coating will peel or flake. The salt spray test (ASTM B117) exposes coated panels to a corrosive fog, measuring how well the finish protects aluminum over time.

For architectural projects, the American Architectural Manufacturers Association (AAMA) standards set the bar for long-term performance. There are three main classes:

Specifying the correct AAMA class ensures your powder coating process matches the project’s environment and expected service life. For example, a curtain wall on a coastal hospital should meet AAMA 2605, while interior office partitions may only require 2603.

You’ll often see salt spray ratings—like “1,000 hours on aluminum”—in powder coating specs. But what does that really mean? It’s a comparative, not absolute, measure. The test simulates harsh, corrosive conditions and checks how far corrosion creeps from a scribed line. Passing 1,000–1,500 hours (with ≤2–3 mm creepage) is a strong indicator of long-term outdoor durability—but only if the pretreatment, film thickness, and cure are all correct.

Salt spray hours are a benchmark, not a guarantee of years in the field. They’re valid only when pretreatment meets spec, film build is within range, and cure is properly verified. Always specify pretreatment type, powder chemistry, target film thickness, and your method for confirming cure.

Even the best process of powder coating relies on vigilant quality checks. Here’s what to document for every batch:

For critical work, advanced tests like differential scanning calorimetry can further verify cure, but regular field checks—like MEK rubs and cross-hatch adhesion—are often all you need for robust priming powder coating results.

By grounding your project in these standards and test results, you ensure the process of powder coating delivers not just a beautiful finish, but one built to last. Up next, we’ll move from standards to hands-on application—showing you how to set up, mask, and specify powder coated aluminum parts for defect-free results every time.

Ever wondered why some powder coated aluminum parts look flawless while others show edge defects, inconsistent gloss, or even early corrosion? Achieving a durable, attractive finish is about more than just spraying on powder—it’s about a precise powder coat setup, careful masking, solid grounding, and verifying every step along the way. Let’s break down the practical application details that ensure your powder coated aluminum parts meet the highest standards, whether you’re coating window frames or custom extrusions.

When you need crisp lines and protected threads or bearing fits, proper masking is essential. Imagine coating a batch of architectural window frames—if you skip the right masking, you’ll end up with powder where you don’t want it, leading to assembly headaches or rework. Here’s what works best:

Pro tip: Always double-check that masking materials are compatible with both your powder chemistry and oven cycle—some adhesives can leave residues that affect adhesion or appearance.

Great powder coating application is built on solid electrical grounding. Without it, powder won’t transfer efficiently, leading to thin spots or uneven coverage. Here’s how to get it right:

Here’s a quick-reference table for typical settings by part geometry:

| Part Geometry | Gun Distance (cm) | Voltage (kV) | Traverse Speed (cm/s) |

|---|---|---|---|

| Flat Panels | 20–25 | 60–90 | 30–40 |

| Extrusions (Open) | 15–20 | 50–70 | 20–30 |

| Deep Channels/Recesses | 10–15 | 40–60 | 10–20 |

Remember, every powder coating application should include a visual inspection after cure—look for uniform color, gloss, and edge coverage. If you spot issues, adjust your gun distance or voltage for the next batch.

Ready to specify powder coated aluminum parts for your next project? Use this proven specification block to communicate exactly what you need to your coater or supplier:

Powder: TGIC polyester meeting AAMA 2604

Film Thickness: 60–80 µm

Cure: 190°C for 12 min at part metal temperature

Pretreatment: Non-chrome zirconium per supplier TDS

DI Final Rinse: ≤30 µS/cm

Adhesion: ASTM D3359 5B

Gloss: ASTM D523 30 ± 5 GU (60°)

Salt Spray: ≥1,000 h per ASTM B117 to scribed panel with creepage ≤3 mm

Color: ΔE ≤2.0 vs standard

Including these details in your powder coat setup ensures consistency and performance—no matter who’s applying the finish.

If you’re specifying extruded frames or components and asking can you powder coat aluminum for architecture, it’s smart to partner with a supplier who understands both extrusion and finishing. Shengxin, a professional manufacturer, supplies engineered extrusions ready for pretreatment and coating—aligning design, alloy, and finish requirements from day one. Explore their capabilities for aluminum extrusion profiles China to streamline your next project.

By mastering your powder coating application and setup, you’ll ensure every batch of powder coated aluminum parts meets both your aesthetic and durability goals. Next, we’ll dive into troubleshooting—so you can quickly fix defects and keep your line running smoothly.

Ever pulled a fresh batch of powder coated aluminum parts from the oven, only to spot orange peel, fisheyes, or patchy color? Even with a dialed-in process, defects can pop up unexpectedly. The good news: most issues have clear root causes and practical fixes. Here’s how to identify, test, and correct common problems—so your line keeps running and your finishes keep lasting.

| Defect | Quick Test | Corrective Action |

|---|---|---|

| Orange peel | Visual, film gauge | Reduce film build, adjust oven, verify cure window |

| Fisheyes | Visual, water-break test | Improve cleaning, exclude silicones, filter air |

| Blistering | Visual, MEK rub | Increase dry-off, verify metal temp, extend flash |

| Poor adhesion | Cross-hatch (ASTM D3359) | Audit pretreatment, titration, DI rinse |

| Pinholing/outgassing | Visual, magnifier | Pre-bake, use outgas-tolerant powders |

| Color variation | Visual, gloss meter | Standardize settings, control batches |

| Sagging | Visual, film gauge | Lower preheat, reduce powder passes |

How do you know your finish will last? Two simple field tests give you confidence:

Perform these checks on first-off parts every shift—especially after changing powder batches or oven settings. They’re fast, low-cost, and catch problems before they leave your shop.

Sometimes, defects are too severe for touch-up or spot repair. That’s when you need to know how to remove powder coating from aluminium safely and efficiently. Here’s how:

After stripping, always fully re-pretreat the aluminum before recoating—clean, etch, conversion coat, rinse, and dry. This ensures the new powder coat bonds just as well as the original.

Curious about special cases? Many ask, can you powder coat over anodized aluminum? The answer is yes: for new anodized aluminum, a light sanding and acetone wipe may be enough; for older, weathered anodize, abrasive blasting is best before powder coating. As always, surface prep is the key to a durable, defect-free finish.

Shop-Floor Checklist:

- Verify ground (<1 Ω)

- Check DI rinse ≤30 µS/cm

- Measure film thickness

- Confirm metal-temp cure

- Perform D3359 adhesion and MEK rubs on first-off parts every shift

By understanding the root causes, using quick field tests, and knowing how to remove powder coating from aluminium or rework as needed, you can keep your operation efficient and your finishes first-rate. Next, we’ll cover how to extend the life of your powder coated aluminum parts with smart maintenance and recoat strategies.

Ever wondered how long your powder coated aluminum windows or powder coated aluminum fencing will last before they need serious attention? The answer depends on both the powder chemistry you choose and the environment where your aluminum lives. With proper specification and care, you’ll notice that powder coated aluminum furniture and architectural features can look vibrant and resist corrosion for many years. Here’s a quick look at typical maintenance intervals based on real-world conditions and widely accepted industry standards:

| Environment | Polyester Powder | FEVE (Fluoropolymer) Powder |

|---|---|---|

| Inland Urban | 10–15 years | 20+ years |

| Coastal/Marine | 7–10 years | 15–20+ years |

| Industrial/High Pollution | 8–12 years | 15–18 years |

These estimates assume an AAMA-compliant powder system and a film thickness of 60–80 microns. Regular inspection and cleaning can further extend these timelines, especially for high-touch or exposed installations.

When you think about maintenance, imagine this: a light cleaning every few months can make the difference between a finish that lasts decades and one that fails early. For powder coated aluminum windows and powder coated aluminum fencing, cleaning is straightforward:

In coastal or industrial areas, increase cleaning frequency to quarterly or even monthly. For all environments, avoid strong alkalis, acids, or power washers—these can damage the powder coating and void your warranty.

For powder coated aluminum furniture in high-use areas, check regularly for dirt, debris, or plant contact that could trap moisture and accelerate wear. Trimming nearby shrubs and keeping lawn equipment away will help prevent accidental scratches or chips.

Even the best finishes can get scratched or chipped over time. The good news? Most minor blemishes are easy to repair, and clear coat powder coating aluminum can help extend the life and gloss of metallic or dark-colored finishes. Here’s how to approach maintenance and repair:

Document all cleaning and maintenance activities in your O&M (Operations & Maintenance) manual. Using improper cleaners or skipping scheduled care can void many powder coating warranties and shorten the life of your finish.

Pairing regular, gentle cleaning with timely repairs and the right recoating strategy will help your powder coated aluminum windows, fencing, and furniture maintain their appearance and performance for years to come. Up next, we’ll explore how to select the right supplier and finalize your powder coated aluminum specification for maximum project success.

When you’re ready to specify powder coated aluminum for your next project, the supplier you choose can make or break your results. Imagine investing in a beautiful facade or a fleet of powder coated aluminum parts—only to face early color fade, adhesion failure, or costly delays. To avoid these headaches, you’ll want a partner who understands not just the basics, but the full journey from alloy selection through finishing and quality control.

| Supplier | Capabilities | Standards (AAMA/ASTM) | Pretreatment (Non-chrome) | Oven Profiling | MOQ / Lead Time | Documentation |

|---|---|---|---|---|---|---|

| Shengxin | Integrated extrusion + finishing; engineering guidance for drainage, fixturing, masking | AAMA 2603/2604/2605, ASTM D3359, D523, B117 | Yes (zirconium, titanium, or chromate per spec) | Full oven profiling and batch logging | Flexible MOQ; lead time by project | Robust QA docs, first-article samples, batch certs |

| Local job coater | Short-run, custom parts; basic masking/fixturing | Varies—confirm aluminum-specific experience | Check for non-chrome or chromate options | Manual or semi-auto; may lack full traceability | Low MOQ; fast turnaround | Basic inspection, limited batch records |

| Integrated façade fabricator | Turnkey design, extrusion, and finishing | AAMA 2604/2605, project-specific testing | Typically yes; confirm per spec | Automated profiling, project logs | Project-based; longer lead times | Full project documentation, site support |

Sounds complex? It doesn’t have to be. The best results come when your supplier manages both the extrusion and powder coating processes in-house. Why? Because every step—from alloy selection to surface prep—affects the final finish. When you work with a partner like Shengxin, you get engineered extrusions designed for optimal powder adhesion, consistent oven profiling, and robust QA documentation. This reduces the risk of mismatched tolerances, poor masking, or coating failures down the line. For teams evaluating can you powder coat aluminium at scale, reviewing the capabilities of an integrated supplier is a smart move.

So, can aluminum be powder coated for your application? Absolutely—if you follow a proven process and partner with the right supplier. For architectural extrusions, the best approach is to pair a reputable extrusion source with a powder system meeting AAMA 2604 or 2605. This ensures your powder coated aluminium meets demanding standards for UV stability, corrosion resistance, and long-term color retention. For indoor or semi-exposed parts, hybrids or epoxies may maximize chemical resistance and cost efficiency.

Remember, the success of powder coating aluminum parts depends on more than just the powder—it’s about the synergy between alloy, pretreatment, application, and quality assurance. Document your specification using the templates provided above, validate with first-article testing, and maintain open communication with your supplier throughout production.

If you’re sourcing at scale or need engineered support, consider requesting finish samples and a technical review from aluminum extrusion profiles China to see how integrated extrusion and finishing can streamline your next project.

Choosing the right partner ensures your powder coated aluminium performs beautifully and reliably—whether it’s for a landmark building, industrial equipment, or custom components. With careful supplier selection and robust quality control, your investment in powder coated aluminum will deliver results that last.

Yes, aluminum can be powder coated, offering superior durability, color stability, and corrosion resistance compared to painting. Powder coating forms a thicker, more protective layer, is available in a wider range of colors and textures, and typically lasts much longer outdoors. Unlike paint, it is also more environmentally friendly and requires less maintenance over its lifespan.

The essential steps include thorough cleaning and degreasing, etching or deoxidizing to remove the natural oxide layer, applying a conversion coating for adhesion and corrosion resistance, rinsing and drying, masking as needed, electrostatic powder application, and curing at the correct metal temperature. Each step is crucial to ensure a durable, high-quality finish.

Absolutely. Aluminum must be carefully pretreated because its natural oxide layer can prevent proper adhesion. Pretreatment typically involves alkaline cleaning, etching, deoxidizing, and applying a conversion coating such as chromate or non-chrome zirconium. This process ensures the powder coat bonds securely and resists corrosion.

With correct preparation and powder chemistry, powder coated aluminum can last 10–20 years in urban or inland environments and 7–15+ years in coastal or industrial settings. Choosing the right powder type, maintaining proper film thickness, and performing regular cleaning are key to maximizing lifespan.

Yes, powder coating can be applied over anodized aluminum. For new anodized surfaces, light sanding and solvent wiping may be sufficient. For older or weathered anodized aluminum, abrasive blasting is recommended to ensure proper adhesion. Always follow with full pretreatment before applying the powder coat.

online service

online service 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360