Ever wondered why so many modern buildings and high-performance products have that sleek, metallic look that seems to last for years? The answer often lies in the use of clear anodized aluminum. But what is clear anodized aluminum, and why has it become a go-to choice for architects, manufacturers, and designers?

Imagine you’re designing a storefront, a set of window frames, or a custom electronics enclosure. You want something that’s not just attractive, but also tough enough to withstand daily wear, weather, and time. Clear anodized aluminum offers a solution that checks all those boxes—and more.

At its core, anodizing is an electrochemical process that transforms the surface of aluminum. During this process, the aluminum part is immersed in an acid electrolyte bath and subjected to an electric current. This causes the metal’s surface to grow a controlled, thicker oxide layer. The result? A finish that’s significantly more durable, corrosion-resistant, and visually appealing than untreated aluminum (Want.net).

So, when you see a product with a clear anodized aluminum finish, you’re looking at aluminum that’s been fortified without hiding its metallic character. This finish is neither painted nor coated in the traditional sense—it’s a transparent or slightly frosted layer that preserves the base metal’s look while adding serious performance benefits.

This material’s popularity isn’t just about its clean, modern style. It’s also about how it bridges the gap between aesthetics and engineering. Whether you’re specifying materials for a high-traffic public building or crafting a precision part for electronics, clear anodized aluminum delivers:

Throughout this guide, you’ll discover the ins and outs of clear anodized aluminum—from its defining features and benefits to how it’s made, where it’s used, and the best ways to care for it. Ready to see why this finish is trusted in everything from architecture to advanced manufacturing? Let’s dive in.

When you hear “clear anodized aluminum,” what exactly does that mean? Is it just shiny metal, or is there more beneath the surface? If you’ve ever wondered why some aluminum parts look pristine for years while others quickly dull or corrode, the answer often comes down to this specialized finish.

Clear anodized aluminum is aluminum that has undergone an anodizing process—but without the addition of any dyes or pigments. The result is a transparent, hard oxide layer that enhances the metal’s natural silver-gray color rather than hiding it. Unlike painted or powder-coated aluminum, this finish is not a surface coating that can chip or peel. Instead, it’s an integral part of the metal itself, formed by an electrochemical reaction that thickens the natural oxide layer on the aluminum’s surface (Want.net).

Variations such as clear satin anodized aluminum offer a soft, matte sheen, while clear hard anodized aluminum features an even thicker, more wear-resistant layer suited for heavy-duty or industrial applications.

So, what are the real benefits of clear anodized aluminum? Here’s why this finish is so widely trusted across industries, from architecture to electronics:

Still debating between clear anodized aluminum and other options? Consider this: the anodized layer doesn’t just sit on top of the metal—it becomes a part of it. That means no chipping, flaking, or fading. Plus, with options like clear satin or hard anodized finishes, you can fine-tune the look and performance for everything from decorative trim to rugged outdoor equipment.

With these advantages in mind, it’s easy to see why clear anodized aluminum is a favorite for applications where longevity, appearance, and practicality all matter. Next, let’s take a closer look at the distinctive look and feel of this finish, and how it compares visually to other aluminum treatments.

When you run your hand across a piece of clear anodized aluminum, what stands out? Is it the color, the texture, or the way it interacts with light? Let’s break down what makes this finish so visually and physically unique—and why it’s become a favorite for everything from modern architecture to high-end electronics.

First, let’s tackle the question: What is the clear anodized aluminum color? Despite the word “clear,” this finish isn’t glassy or transparent. Instead, the anodizing process creates a colorless, transparent oxide layer that enhances the underlying metal’s natural appearance. The result is typically a silver or natural metallic tone—think of a clean, industrial gray that feels neutral yet sophisticated (Diecasting-Mould.com). The finish can range from matte to a subtle satin sheen, depending on how the aluminum is prepped before anodizing and the specific process parameters used (Want.net).

Unlike painted or powder-coated aluminum, anodized clear aluminum does not introduce color or obscure the metal’s grain and texture. This means you get a finish that feels authentic, with a modern, minimalist vibe.

Touch a piece of clear anodized aluminum, and you’ll notice it’s smooth, hard, and cool to the touch. The anodized layer is much harder than raw aluminum, giving the surface a crisp, almost glass-like feel—without being slippery. This hardness also means it resists scratches and dents far better than untreated aluminum.

Compared to painted or powder-coated finishes, clear anodized aluminum offers a more tactile, premium feel. Paint and powder coat add a soft or sometimes slightly textured layer, but they can mask the metal’s natural qualities and may chip or flake over time. In contrast, anodizing preserves the feel of real metal while enhancing durability (WayKenRM).

One of the most interesting aspects of clear anodized aluminum is how it interacts with light. Under direct sunlight or strong indoor lighting, the finish can appear brighter and more reflective, emphasizing the metal’s subtle grain and giving it a dynamic, ever-changing look. In softer or indirect lighting, the surface takes on a more muted, matte tone—ideal for blending into minimalist or industrial design schemes.

Because the anodized layer is transparent, any underlying texture—whether brushed, matte, or polished—remains visible, allowing for a wide range of customization. This adaptability is why you’ll find clear anodized aluminum on everything from sleek electronics to building facades.

| Finish Type | Appearance | Texture | Durability |

|---|---|---|---|

| Raw Aluminum | Silvery, can dull or oxidize | May have machining marks | Prone to scratches, corrosion |

| Clear Anodized | Natural metallic, matte to satin | Smooth, hard, cool | Highly resistant to wear, corrosion |

| Painted | Variety of colors, can chip | Soft, may mask metal feel | Surface can peel or scratch |

| Powder Coated | Wide color/texture options | Thicker, sometimes rough | Durable, but can chip under impact |

In summary, clear anodized aluminum offers a distinctive, modern look that’s both understated and robust. Its ability to showcase the true character of aluminum—while providing a hard, resilient surface—makes it the finish of choice for designers and engineers who want both beauty and performance. As you move forward, understanding these aesthetic and tactile qualities will help you select the right finish for your next project. Next, we’ll explore exactly how this finish is created and what sets the clear anodizing process apart.

Ever wondered why some aluminum products look flawlessly uniform and last for years—even in tough, outdoor environments? The secret lies in the clear anodized aluminum process. While the science behind clear anodizing aluminum might sound complex, breaking it down into simple steps reveals how each stage transforms raw metal into a durable, elegant finish. Let’s walk through the journey from raw aluminum to a pristine, corrosion-resistant surface.

The clear anodizing aluminum process is more than a single chemical dip—it’s a carefully controlled, multi-step procedure. Each stage is crucial for achieving a finish that’s not only visually appealing but also tough enough to stand the test of time. Here’s how it works:

It’s tempting to think anodizing is a one-size-fits-all process, but the reality is that consistent, high-quality results demand expertise, advanced equipment, and careful communication between customer and anodizer. Even small variations in cleaning, solution chemistry, or electrical current can affect the final color, texture, or durability of the finish (AluConsult).

Leading manufacturers invest in specialized anodizing lines and skilled technicians to ensure every batch meets strict specifications. For example, companies with dedicated anodizing facilities can tailor the process to different aluminum alloys, product shapes, and performance requirements—crucial for architectural, automotive, or industrial applications where quality can’t be compromised.

Before starting a project, it’s wise to discuss your needs with your anodizing partner: What alloy is being used? What will the part be exposed to? Do you want a matte or satin look? These details help ensure the right process parameters are chosen, resulting in a finish that’s both beautiful and built to last.

Understanding the clear anodized aluminum process isn’t just for engineers or manufacturers—it empowers anyone selecting materials for a project to ask the right questions and expect the best results. Next, let’s look at how these expertly finished materials are put to use in architecture and design, and why clear anodized aluminum is the go-to choice for so many demanding applications.

When you walk through a bustling city center or step into a modern office building, have you ever noticed the sleek, metallic frames around windows and doors? Or the clean lines of railings, partitions, and signage that seem to withstand years of use without losing their appeal? Chances are, you’re seeing the quiet strength and style of clear anodized aluminum in action.

Architects and builders are always on the lookout for materials that combine beauty, performance, and sustainability. Clear anodized aluminum checks all these boxes, making it a top choice for both interior and exterior projects. But what makes it so well-suited for demanding architectural environments?

Let’s break down some of the most common architectural applications. If you’re planning a project, here’s where you’ll often find clear anodized aluminum making a difference:

Every building is different, and so are its design requirements. That’s why leading manufacturers offer a wide range of custom aluminum extrusion profiles—from simple angles and channels to complex shapes tailored for unique projects. Companies with advanced fabrication capabilities can deliver not just standard sizes, but also bespoke solutions that match your exact specifications (FONNOV Aluminium).

For example, if your project calls for a special storefront mullion, a uniquely shaped window frame, or a decorative panel with intricate cutouts, partnering with a manufacturer experienced in both anodizing and custom extrusion ensures you get the finish, fit, and performance you need.

When specifying clear anodized aluminum for your next building, look for suppliers who adhere to rigorous quality standards—such as AAMA 611 for architectural finishes—and who can provide documentation on coating thickness, color consistency, and durability testing. This attention to detail ensures your finished project not only looks stunning on day one, but continues to perform for years to come.

With its blend of technical advantages and design flexibility, clear anodized aluminum remains a cornerstone of modern architecture. Next, we’ll explore the different product forms available and how to select the right profile for your application—helping you turn your architectural vision into a durable, beautiful reality.

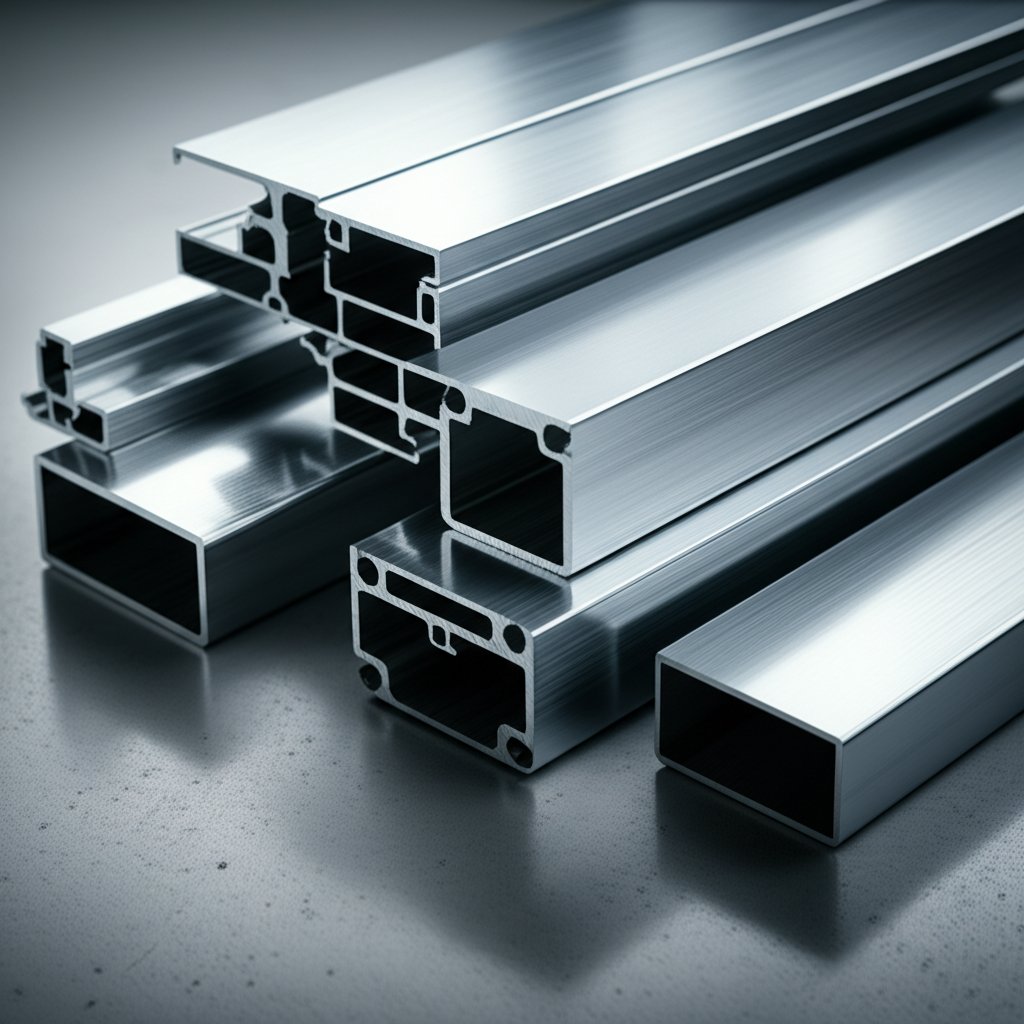

When planning your next architectural or industrial project, have you ever wondered how clear anodized aluminum is supplied and shaped to fit so many different applications? The answer lies in its remarkable versatility. From sleek window frames to robust structural supports, this finish is available in a wide range of forms—each tailored for specific uses. Let’s explore the most common profiles you’ll encounter, and how each one contributes to modern design and engineering.

Clear anodized aluminum isn’t limited to a single shape or thickness. Thanks to advanced extrusion and fabrication methods, you’ll find it in profiles that suit everything from minimalist facades to heavy-duty frameworks. Here are the primary forms you’re likely to see:

Imagine you’re outfitting a modern storefront. You might specify clear anodized aluminum sheet for the exterior cladding, angles for reinforcing the window frames, and channels to secure glass panels. For a commercial office interior, tubes could form the basis of clean-lined railings or modular partitions, while custom extrusions create branded signage or unique door hardware. Each form is designed to maximize both function and aesthetics, with the anodized finish providing the durability and low maintenance required for busy environments.

While the focus here is on architectural and industrial profiles, it’s worth noting that clear anodized aluminum also appears in consumer products. For example, its non-reactive, easy-to-clean surface is valued in cookware and appliance trim. However, the lion’s share of demand comes from construction, where performance and appearance must go hand-in-hand.

With so many options—from the simplicity of a clear anodized aluminum sheet to the engineered precision of custom angles and channels—selecting the right form depends on your project’s structural needs, design goals, and environmental conditions. Working with experienced suppliers ensures you get profiles that meet industry standards for quality, finish consistency, and long-term performance.

Now that you know the forms and profiles available, it’s crucial to understand how to keep these surfaces looking their best. Next, we’ll cover the most effective cleaning techniques for anodized aluminum, so your investment maintains its beauty and integrity for years to come.

Ever notice how some aluminum window frames or architectural panels seem to stay spotless year after year, while others quickly show grime or streaks? The secret isn’t just the material—it’s knowing how to clean anodized aluminum the right way. Whether you’re maintaining a storefront, a set of railings, or decorative panels, these practical steps will help you keep your clear anodized aluminum looking its best for the long haul.

Sounds complex? It’s actually quite simple. Here’s a go-to routine you can follow for most situations:

Think all cleaners are safe? Not quite. Here’s what you should steer clear of to protect your investment:

By following these simple but effective cleaning techniques, you’ll preserve the beauty and resilience of your clear anodized aluminum for years to come. Next, we’ll tackle what to do if scratches or minor damage do occur—so you’re fully equipped to keep every surface in top shape.

Ever noticed a scratch or scuff on your clear anodized aluminum and wondered, “Is this permanent?” Before you worry about costly repairs or replacements, it’s important to know that not all marks are created equal—and many can be fixed with simple steps. Let’s break down how to handle everything from light blemishes to deeper scratches, using real-world examples and practical advice.

When you see a line or blemish on your anodized aluminum, ask yourself: is it a true scratch, or just residue from something that rubbed against the surface? The anodized layer is quite hard, so what looks like a scratch is often just a mark left by another material. For instance, keys, rings, or even metal tools can deposit residue, making the surface appear scratched when it’s actually not (Clopay Support).

If cleaning doesn’t work and the scratch is deep enough to reveal bare aluminum, options become more limited. Here’s what you can do:

In summary, most minor scuffs on clear anodized aluminum are easier to fix than they appear. Start with gentle cleaning, try touch up options for deeper marks, and reserve replacement for severe or highly visible damage. By handling scratches carefully, you’ll preserve the beauty and longevity of your anodized surfaces. Next, let’s explore what happens if you want to paint or coat over an anodized finish—and the best practices for doing so.

Ever wondered, can you paint clear anodized aluminum? Or maybe you’re curious if adding a clear coat anodized aluminum finish will boost durability or change the look? These are common questions, especially when you want to refresh, repair, or customize anodized surfaces. Let’s break down the facts, challenges, and best practices so you can make confident decisions for your project.

The short answer is yes—you can paint clear anodized aluminum. But there’s a catch: anodized surfaces are much less porous than bare metal or other finishes, so paint adhesion can be tricky. Skip the right prep, and your new paint job might peel or flake within weeks. Done properly, however, painting can restore appearance, match a specific color scheme, or add extra protection against weather and wear (Kingsun Machining).

Imagine you’re updating faded window frames or giving a second life to a scratched panel. Here’s how to ensure your paint lasts:

Not all paints are created equal, especially for anodized aluminum. Here’s what works best:

Adding a clear coat over anodized aluminum isn’t always necessary, but it can offer extra benefits in certain situations:

Application tips: As with paint, surface prep is key. Clean, lightly abrade, and make sure any previous coatings are fully cured. Select a clear coat compatible with aluminum and with the underlying paint or primer, if present.

In summary, painting or coating clear anodized aluminum is entirely possible with the right preparation and materials. Whether you want to refresh a faded surface, customize a color, or add a clear protective layer, following these steps ensures a durable, attractive finish. Next, we’ll wrap up with a summary of key takeaways and guidance on choosing the best partners and products for your aluminum projects.

When you’re weighing materials for your next architectural, industrial, or design project, it’s easy to get lost in a sea of options. But what if you could choose a finish that combines durability, easy upkeep, and timeless style—all in one? That’s exactly what clear anodized aluminum brings to the table. Let’s recap why this finish stands out and how it could be the smart solution for your needs.

Imagine walking through a city center, entering a sunlit office, or handling a precision electronic device—chances are, clear anodized aluminum is there, quietly doing its job. Its versatility makes it ideal for:

No matter the application, you’ll benefit from a finish that’s as tough as it is attractive—and that requires minimal effort to keep looking its best.

Of course, not all anodized aluminum is created equal. For consistent color, flawless finish, and long-term performance, it pays to work with manufacturers who bring expertise and advanced capabilities to the table. This is where a trusted partner like Shengxin Aluminum can make all the difference. With state-of-the-art facilities, strict quality controls, and a commitment to sustainability, Shengxin delivers high-quality aluminum profiles tailored to your project’s needs (Shengxin Aluminium).

So, whether you’re designing a landmark building, engineering a new product, or simply seeking a finish that stands the test of time, consider the value of clear anodized aluminum—and the expertise of proven manufacturers—to bring your vision to life. Ready to explore your options? Connect with industry leaders and discover how the right finish can elevate your next project.

Clear anodized aluminum features a thin, transparent oxide layer that enhances corrosion resistance and maintains the metal's natural look. Hard anodized aluminum, by contrast, has a much thicker and denser oxide coating, making it even more wear-resistant and suitable for heavy-duty or industrial applications. Both are achieved via anodizing, but the process parameters differ to meet specific performance needs.

Yes, painting over clear anodized aluminum is possible with proper preparation. The surface must be thoroughly cleaned and lightly abraded to promote adhesion, by an appropriate primer designed for aluminum. Oil-based, acrylic, or polyurethane paints can then be applied. For best results and long-term durability, follow each manufacturer's instructions carefully.

Clear anodized aluminum is favored in architecture for its exceptional durability, corrosion resistance, and timeless metallic finish. It requires minimal maintenance, resists fading and scratching, and is eco-friendly due to its recyclable nature. Its neutral appearance complements various design styles and is commonly used in storefronts, windows, curtain walls, and railings.

To clean clear anodized aluminum, use a mild soap solution and a soft cloth or sponge. Rinse thoroughly with clean water and dry with a lint-free cloth to prevent streaks. Avoid abrasive cleaners, harsh chemicals, and steel wool, as these can damage the anodized layer. Regular gentle cleaning helps maintain the finish’s appearance and longevity.

For light scuffs or marks, gentle cleaning with mild soap and a soft cloth usually suffices. Deeper scratches that expose bare metal may require touch up paint or a specialized pen, though perfect color matching can be challenging. For significant or highly visible damage, replacement of the affected part is often the best solution.

online service

online service 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360