Imagine the convenience of easily attaching insect screens or seasonal decorations to your windows without the need for drilling or permanent fixtures. This is where Velcro comes into play, offering a versatile and temporary solution that can be effortlessly applied to aluminum window frames. Velcro, known for its ingenious hook-and-loop fastening system, can transform how you interact with your home’s windows, providing flexibility and ease of use.

Using Velcro on aluminum windows is particularly beneficial for those who prefer a no-drill approach. This method not only preserves the integrity of your window frames but also allows for quick and easy changes. Whether you're swapping out insect screens in the summer or hanging festive decorations during the holidays, Velcro tape for windows offers a practical solution that can be adjusted as needed.

However, sticking Velcro to aluminum isn't without its challenges. Aluminum's naturally smooth surface and the presence of an oxide layer can complicate adhesion. These factors reduce the contact area for the adhesive, potentially weakening the bond. But don't worry—there are effective strategies to overcome these obstacles. By preparing the surface properly and selecting the right adhesive-backed Velcro, you can achieve a strong and lasting bond.

For those interested in exploring this topic further, a comprehensive guide on the subject can be found at Shengxin Aluminum, which provides surprising solutions and insights into how Velcro can be effectively used on aluminum surfaces.

In the following sections, we will delve deeper into understanding the mechanics of Velcro adhesion, the types of Velcro best suited for aluminum, and the steps necessary to ensure a secure application. Stay tuned to learn how to optimize Velcro's potential on your aluminum window frames, making your home more adaptable and functional.

Have you ever wondered why some Velcro applications hold firm while others seem to fall apart? The secret often lies in the type of adhesive used and the surface properties of the material to which it is applied. When it comes to aluminum windows, understanding these elements is crucial for achieving a secure bond.

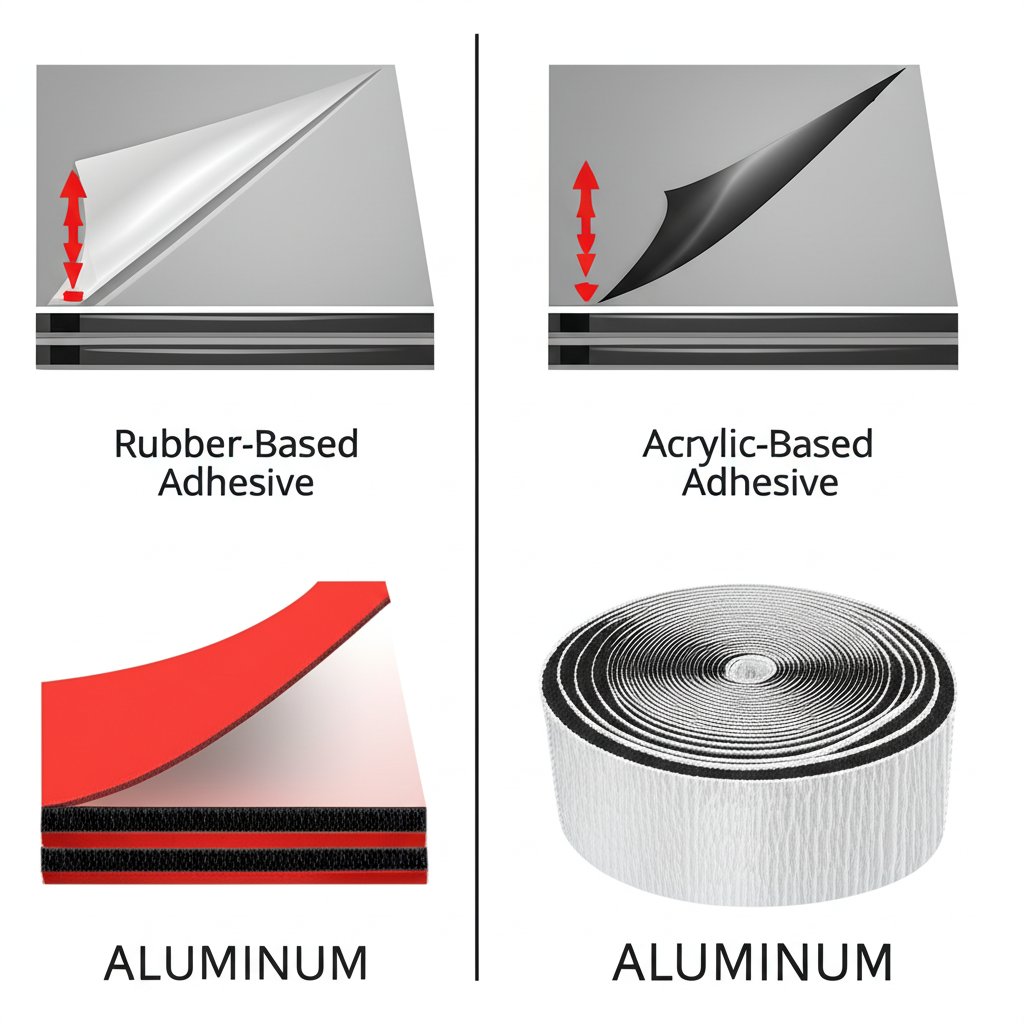

Adhesive-backed Velcro is a versatile tool, utilizing a pressure-sensitive adhesive that bonds to various surfaces. This adhesive is typically pre-applied to the Velcro, making it easy to use—simply peel off the backing and press it onto the desired surface. However, not all adhesives are created equal, and the choice between rubber-based and acrylic-based adhesives can significantly impact performance.

Aluminum surfaces present unique challenges for adhesion due to their smoothness and the presence of an oxide layer. This oxide layer forms naturally when aluminum is exposed to air, creating a barrier that can hinder adhesive performance. To combat this, proper surface preparation is essential.

Before applying Velcro, ensure the aluminum surface is clean and free of dust or grease, as these can significantly reduce adhesion. A clean surface maximizes contact between the adhesive and the metal, enhancing the bond's strength.

Selecting the appropriate Velcro product is critical. For aluminum windows, adhesive Velcro for aluminum should be chosen based on the environment and the load it needs to support. Industrial-strength Velcro or products specifically designed for outdoor use can provide the durability required for more demanding applications.

By understanding the basics of Velcro adhesion and the characteristics of aluminum surfaces, you can make informed choices that ensure a reliable and lasting bond. As we move forward, we'll explore how to select the right Velcro product for your specific needs, ensuring your applications are both effective and durable.

When it comes to sticking Velcro on aluminum windows, choosing the right type of Velcro is crucial for ensuring a secure and lasting bond. The selection process involves considering several factors, such as the weight of the item being supported, the environmental conditions, and the specific characteristics of the aluminum surface. Let's explore how to make the best choice for your needs.

Here are some types of Velcro that are particularly well-suited for aluminum window applications:

To ensure optimal performance, follow these best practices when selecting Velcro for your aluminum windows:

By carefully selecting the right type of Velcro and considering the unique requirements of your aluminum window application, you can achieve a secure and lasting bond that meets your needs. As we move forward, we'll delve into the essential tools and materials needed for a successful Velcro application, ensuring you're fully prepared for the task ahead.

Before embarking on the task of sticking Velcro to your aluminum windows, it's crucial to gather all the necessary tools and materials. Proper preparation not only ensures a smooth application process but also enhances the durability of the bond. Here's a comprehensive list of what you'll need:

By equipping yourself with these essential tools and materials, you'll be well-prepared to apply Velcro to your aluminum windows effectively. This preparation is key to achieving a secure and lasting bond, ensuring your Velcro applications stand the test of time. In the following section, we'll walk you through the step-by-step process of applying Velcro to aluminum windows, ensuring a seamless and reliable installation.

Sticking Velcro on aluminum windows might seem daunting due to the metal's smooth surface and oxide layer, but with the right approach, you can achieve a strong and lasting bond. Here’s a detailed guide on how to apply Velcro to aluminum, ensuring optimal adhesion and functionality.

Before applying Velcro, it’s crucial to prepare the aluminum surface properly. Start by cleaning the window frame with isopropyl alcohol to remove any dust, grease, or dirt. This step is vital because any debris can significantly reduce the adhesive's effectiveness. Once cleaned, lightly sand the surface using fine-grit sandpaper or an abrasive pad. This process will create a rough texture, enhancing the adhesive's grip on the aluminum.

Select a Velcro product that suits the environmental conditions and the weight of the item you plan to attach. For outdoor applications, use Velcro with acrylic-based adhesives, as they offer superior resistance to moisture and temperature fluctuations. Industrial-strength Velcro is recommended for heavier items due to its robust holding power.

Use a measuring tape to determine the exact length of Velcro needed for your application. Cut the Velcro to size with scissors or a utility knife, ensuring the edges are clean for a seamless fit. Precision in this step helps prevent waste and ensures the Velcro covers the desired area effectively.

Peel off the backing from the adhesive side of the Velcro and carefully position it on the prepared aluminum surface. Press firmly, using a rubber roller or a firm pressing tool to smooth out the Velcro and eliminate any air bubbles. This step ensures maximum contact between the adhesive and the aluminum, enhancing the bond's strength.

After applying the Velcro, it's important to let the adhesive cure. Depending on the adhesive type, this can take anywhere from 24 to 72 hours. During this time, avoid placing any weight on the Velcro to ensure a secure bond develops.

By following these steps, you'll notice a significant improvement in the adhesion of Velcro to your aluminum windows, enabling you to utilize this versatile fastening solution effectively. In the next section, we will delve deeper into the importance of surface preparation and how it contributes to the success of your Velcro application.

When it comes to achieving a strong adhesion of Velcro on aluminum windows, surface preparation is paramount. Aluminum, known for its smooth surface and protective oxide layer, can pose challenges for adhesive applications. However, with the right preparation techniques, you can significantly enhance the bond strength, ensuring that your Velcro applications stand the test of time.

Before applying Velcro, it is crucial to clean the aluminum surface thoroughly. Begin by using a 50:50 mixture of isopropyl alcohol and water. This solution effectively removes oils, dust, and other contaminants that could hinder adhesion. For surfaces with heavy grease or oil, a degreaser might be necessary, by an IPA/water cleaning to ensure all residues are eliminated (source). This step is critical as any remaining dirt can prevent the adhesive from forming a strong bond.

Once the surface is clean, lightly abrade it using fine-grit sandpaper or an abrasive pad. This process not only removes the oxide layer but also creates a rougher texture, increasing the surface area for the adhesive to grip. This simple step can make a significant difference in the longevity and strength of the Velcro bond.

For even better results, consider applying an adhesion promoter or primer. These products are designed to enhance the adhesive's performance, especially on challenging surfaces like aluminum. By priming the surface, you can improve both the initial tack and the long-term durability of the Velcro application.

In the realm of aluminum products, Shengxin Aluminum stands out for its high-quality profiles. Known for their durable and corrosion-resistant finishes, Shengxin's aluminum profiles are an excellent choice for projects requiring robust and reliable materials. Their anodizing process, which enhances the protective qualities of aluminum, makes their profiles particularly well-suited for applications involving adhesive products like Velcro (source).

By taking the time to prepare your aluminum surfaces properly, you ensure that your Velcro applications are both effective and durable. As we move forward, we'll explore common issues that might arise during the application process and offer solutions to maintain the integrity of your Velcro bond over time.

Even with meticulous preparation and application, challenges can arise when sticking Velcro to aluminum windows. Understanding these potential issues and knowing how to address them is key to maintaining a strong and lasting bond.

One frequent problem is the failure of Velcro to adhere properly due to the smoothness of aluminum surfaces and the presence of an oxide layer. This can be exacerbated by environmental factors such as moisture and temperature fluctuations. To combat these issues, ensure the surface is thoroughly cleaned and consider using an adhesion promoter to enhance the bond.

Another issue is the gradual loss of adhesion over time, often due to debris accumulation in the Velcro hooks. Regular cleaning of the Velcro using a toothbrush or a fine-tooth comb can help maintain its gripping power by removing lint and other particles that impede adhesion (source).

To maintain a strong Velcro bond, it’s crucial to periodically inspect the adhesive and reapply or replace the Velcro as needed. Environmental conditions can degrade adhesive strength, so consider using products designed for outdoor use if your application is exposed to the elements.

For applications requiring enhanced durability, Shengxin Aluminum offers high-quality aluminum profiles that provide an excellent substrate for adhesive bonding. Their precision manufacturing and surface treatments ensure a reliable foundation for Velcro applications, supporting long-term adhesion (source).

By addressing these common challenges and implementing preventive measures, you can ensure that your Velcro applications on aluminum windows remain effective and durable over time. As we move to the conclusion, we'll summarize the benefits and key takeaways of using Velcro on aluminum surfaces, highlighting the flexibility and convenience it offers.

Incorporating Velcro into your aluminum window setup offers a myriad of benefits that cater to both functionality and aesthetics. This versatile fastening solution allows for easy installation and removal of items like insect screens or decorative elements, providing a hassle-free, no-drill option that preserves the integrity of your window frames. With Velcro, you gain the flexibility to adapt your interior or exterior spaces as needed, ensuring your home remains as dynamic as your lifestyle.

One of the standout advantages of using Velcro on aluminum windows is its ability to form a strong bond without compromising the surface. As we've explored, careful surface preparation and the selection of the right type of Velcro are crucial for achieving optimal adhesion. This ensures that your Velcro applications are both effective and long-lasting, even in challenging conditions.

Additionally, the use of quality materials, such as Shengxin Aluminum's high-grade window profiles, enhances the overall durability and performance of your window solutions. Shengxin's commitment to excellence in aluminum manufacturing ensures that their products provide a robust foundation for any Velcro application, supporting both aesthetic appeal and functional reliability (source).

By embracing Velcro window solutions, you not only enhance the versatility of your living space but also enjoy the peace of mind that comes with using a reliable, adaptable product. Whether you're looking to optimize your home for seasonal changes or simply want to experiment with new decor, Velcro offers an accessible and efficient way to meet your needs.

As you consider the possibilities Velcro brings to your aluminum windows, remember that the key lies in preparation and quality. With the right approach, you can enjoy the full spectrum of benefits that Velcro window solutions offer, transforming your home into a more functional and stylish environment.

Yes, Velcro can stick to aluminum with the right adhesive. Acrylic-based adhesives are recommended for strong adhesion on metal surfaces like aluminum.

To stick Velcro on an aluminum frame, clean the surface with isopropyl alcohol, lightly sand it, and use an acrylic-based adhesive Velcro for optimal results.

Acrylic pressure-sensitive adhesives are ideal for metal surfaces due to their strong tear resistance and ability to withstand moisture and temperature changes.

Ensure the aluminum surface is clean and slightly roughened. Use industrial-strength Velcro for heavier items and allow the adhesive to cure fully for a strong bond.

You'll need adhesive-backed Velcro, cleaning supplies, sandpaper, a measuring tape, scissors, and a rubber roller for a secure application.

online service

online service 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360